Restoring Carburettors - Tips, Methods ?

#1 Restoring Carburettors - Tips, Methods ?

I normally do all my own blasting, but am hesitant about putting bead-blasting anywhere near the SU bodies.

I saw that Simon referred to Soda Blasting here

forum.etypeuk.com/viewtopic.php?f=2&t=6903&p=50521

and sounded very happy - it's not something I've ever used.

You just rinse it all in hot soapy water, it dissolves, you blow everything out with compressed air, that it ?

Could he and/or others confirm what this involved, and just how far / how deep the prior parts-stripping and dismantling has to be first ?

I'd obviously remove everything that's removable.

They're mechanically sound and fresh, but the main bodies are a bit tatty.

And most importantly, if anyone can give me the name of a firm that they've used to confide delicate and expensive stuff like that to, for just such work, I'm all ears - as such skills are short on the ground around here, and I don't want to convert my cabinet over to another media for just one job.

Unless soaking them in Grenache and Carignan has the same effect ? Viognier ?

I saw that Simon referred to Soda Blasting here

forum.etypeuk.com/viewtopic.php?f=2&t=6903&p=50521

and sounded very happy - it's not something I've ever used.

You just rinse it all in hot soapy water, it dissolves, you blow everything out with compressed air, that it ?

Could he and/or others confirm what this involved, and just how far / how deep the prior parts-stripping and dismantling has to be first ?

I'd obviously remove everything that's removable.

They're mechanically sound and fresh, but the main bodies are a bit tatty.

And most importantly, if anyone can give me the name of a firm that they've used to confide delicate and expensive stuff like that to, for just such work, I'm all ears - as such skills are short on the ground around here, and I don't want to convert my cabinet over to another media for just one job.

Unless soaking them in Grenache and Carignan has the same effect ? Viognier ?

Last edited by rfs1957 on Sat Feb 17, 2018 5:47 pm, edited 3 times in total.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#2 Re: Cleaning carburettor bodies - Soda Blasting ?

I routinely bead blast carby bodies. They come up fine.

If you remove the throttle plates for cleaning make sure you use new locking screws when you reassemble.

Andrew.

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#3 Re: Cleaning carburettor bodies - Soda Blasting ?

I would not under any circumstances use NaHCO3 to blast aluminium. It will dissolve the metal.

Chris '67 S1 2+2

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#4 Re: Cleaning carburettor bodies - Soda Blasting ?

I had my carb bodies and manifolds soda blasted. In reality wished I hadn’t bothered.

Yes they came up clean, but not as sparkling clean as I wanted. In addition I spent some time cleaning all of the remaining soda from the bodies and passages. I had fully stripped them prior.

Wouldn’t do it this way again.

Tim

Yes they came up clean, but not as sparkling clean as I wanted. In addition I spent some time cleaning all of the remaining soda from the bodies and passages. I had fully stripped them prior.

Wouldn’t do it this way again.

Tim

Series 1 FHC purchased 40 years ago. Courted my wife in it.

Series 1 2+2 when the kids were small now sold.

Series 1.5 OTS in opalescent maroon, Californian car. My retirement present.

Series 1 2+2 when the kids were small now sold.

Series 1.5 OTS in opalescent maroon, Californian car. My retirement present.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

#5 Re: Cleaning carburettor bodies - Soda Blasting ?

Diecast alloy is fairly delicate stuff and blasting it is likely to pit the surface . The dark coloured stuff which discolours diecast components tends to be resinous deposits from oil and petrol and is not easy to shift. I use a specialist cleaner called ND which is based on, believe it or not, orange peel with a very small amount of alkali in the shape of potassium hydroxide , and which is reuseable . You brush it on over a drip tray, leave it for an hour or so , and then wash off thoroughly leaving a casting shiny like a new one

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#6 Re: Cleaning carburettor bodies - Soda Blasting ?

The carb bodies (and other parts of the manifold and cam covers for example) are made of aluminium or aluminium alloy. Aluminium will react with alkaline solutions and 'dissolve' in them. I would avoid cleaning with any water based product that contained sodium or potassium carbonate/bicarbonate, sodium or potassium hydroxide or any other alkali. All will corrode the metal. Oily deposits can be removed by cleaning with petrol (don't do it in the garage though) using an old tooth brush. Polishing I would use a fine abrasive polish specifically suitable for aluminium such as autosol. Given the delicate precision nature of the carbs I would never blast with anything.

Julian the E-type man

1962 FHC

1966 MGB....fab little car too

1962 FHC

1966 MGB....fab little car too

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#7 Re: Cleaning carburettor bodies - Soda Blasting ?

I've peeled the oranges, Christopher, and got the alkali - what proportions give me ND ?

Can't find this in Carrefour or Intermarché, or anywhere on the internet.

Soda-Blasting (and subsequent washing) is by far and away the most common approach to restoring alloy motorcycle engine cases, I had understood that this was because the solvability of the stuff made it safer to use than glass-beads where - especially on non-die-cast parts - they tend to get stuck and then migrate later into your engine oil.

Can't find this in Carrefour or Intermarché, or anywhere on the internet.

Soda-Blasting (and subsequent washing) is by far and away the most common approach to restoring alloy motorcycle engine cases, I had understood that this was because the solvability of the stuff made it safer to use than glass-beads where - especially on non-die-cast parts - they tend to get stuck and then migrate later into your engine oil.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Gfhug

- Posts: 3305

- Joined: Thu Jun 19, 2014 3:08 pm

- Location: Near Andover, Hampshire,in D.O. Blighty

#8 Re: Cleaning carburettor bodies - Soda Blasting ?

Rory, would it be worth chatting to David Lonsdale who restores carbs what he uses for the bodies?

Nice fellow who may be willing to help, 07786 912011

Lots of elbow grease and diamondbrite for the shiny bits

Geoff

Nice fellow who may be willing to help, 07786 912011

Lots of elbow grease and diamondbrite for the shiny bits

Geoff

S2 FHC Light Blue

S2 OTS LHD - RHD full restoration

S2 OTS LHD - RHD full restoration

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#9 Re: Cleaning carburettor bodies - Soda Blasting ?

Hi Rory...you need to look into Vapour blasting http://www.aquablast.uk.com/what-is-aqua-blast.html i do have a soda blast and have used it......for example on a Coke can it will take the paint/colour off and leave the aluminium with a slight dull finnish......for any type of blasting you need to totally strip down.......my carb bodies came up great with a toothbrush and autosol... Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#10 Re: Cleaning carburettor bodies - Soda Blasting ?

Thanks, but not convinced by this as using glass-beads in water is no different, as regards what can get left behind, as simple bead-blasting.

I have mate with an ultrasonic cleaner he uses on carburettors, and will have a go, but don't think this makes any claims vis bling finish - and it's the bling I want.

I'll just get my hat and go out for a bit.

I have mate with an ultrasonic cleaner he uses on carburettors, and will have a go, but don't think this makes any claims vis bling finish - and it's the bling I want.

I'll just get my hat and go out for a bit.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#11 Re: Cleaning carburettor bodies - Soda Blasting ?

You will only get bling by polishing

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#12 Re: Cleaning carburettor bodies - Soda Blasting ?

Modest bling then - I'd like them "bright but sober" like originals.

Will follow up all these leads and suggestions, contradictory as some of them may be, and let you know what I end up with ; thanks for the various inputs anyway.

Will follow up all these leads and suggestions, contradictory as some of them may be, and let you know what I end up with ; thanks for the various inputs anyway.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#13 Re: Cleaning carburettor bodies - Soda Blasting ?

Rory,

I had my inlet manifolds and the head sodablasted- soda powder is completely soft, feels and looks like flour, and does no harm to eg valve seats ( at least thats whats I was told- everything working well up to date). But the finish is dull and nothing like the original cast look. Acid dipping did not bring that back either.

.

.

This leaves you with carb cleaner etc. and a brush.

I had my inlet manifolds and the head sodablasted- soda powder is completely soft, feels and looks like flour, and does no harm to eg valve seats ( at least thats whats I was told- everything working well up to date). But the finish is dull and nothing like the original cast look. Acid dipping did not bring that back either.

.

.This leaves you with carb cleaner etc. and a brush.

Mark

1963 OTS 880436

1963 OTS 880436

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#14 Re: Cleaning carburettor bodies - Soda Blasting ?

I've had an identical finish to those dull manifolds using Al2O3 as a blasting media.

Chris '67 S1 2+2

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#15 Re: Cleaning carburettor bodies - Soda Blasting ?

Vapour blasted bodies, before and after, leaves a nice dull shine like a fresh casting, wouldn’t use bead or soda personally and make sure you give them a good wash with panel wipe / carb cleaner before assembly, you do get very fine deposits left.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Geoff Green

- Posts: 141

- Joined: Tue Apr 22, 2014 3:13 am

#16 Re: Cleaning carburettor bodies - Soda Blasting ?

Another media is walnut shells crushed. I blasted my manifolds and other aluminum (rear hubs) and it comes out with a finish like the vapor blasting. I will get some photos up this weekend.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#17 Re: Cleaning carburettor bodies - Soda Blasting ?

I should mention that the manifolds in the above photo had been bead blasted in the past, giving a coarser surface to start with. However soda blasting gives alu a dull apperance and quite the contrary to a shining look (I had to re-polish the front center of the cylinder head after sodablasting). Perfect for the natural alu look though.

Mark

1963 OTS 880436

1963 OTS 880436

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#18 Re: Restoring Carburettors - Tips, Methods ?

These comments come from David Lonsdale, with his permission.

I am a professional carburetter restorer and have been at it for many years.

The first point to make is that if you are planning any sort of abrasive blasting the carb bodies must be completely stripped. Throttle spindles, disc, seals must all come out as well as the jet bearing nut. Seals and disc screws will have to be replaced with new upon reassembly.

There are several types of media which can be used.

1. Glass bead in compressed air gives a uniform finish which hides many imperfections but the resulant finish is not quite like the original out-of-the-die. The pressure can be adjusted to vary the finish.

2. Plastic bead in comp air using thermoset plastic gives a finish very like the original, but is only effective if the bodies are undamaged and have not already been glass beadblasted. Due to imperfections in the original material there may be patches of different colour appear.

3. Aqua blasting (glass bead in water) gives a finer finish than 1.

Before blasting the parts must be completely grease-free and dry of oil. After blasting the parts must be completely cleaned by flushing through with paraffin. I do this three times over to ensure no media is left, particularly in the hole where the idle screw sits, and the passage which follows it.

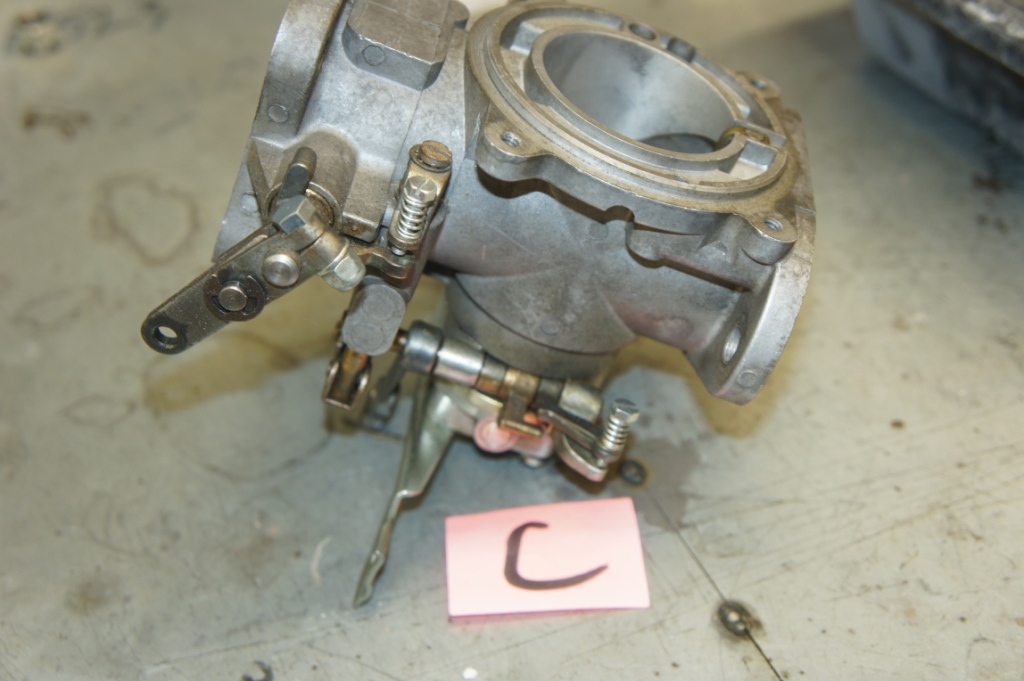

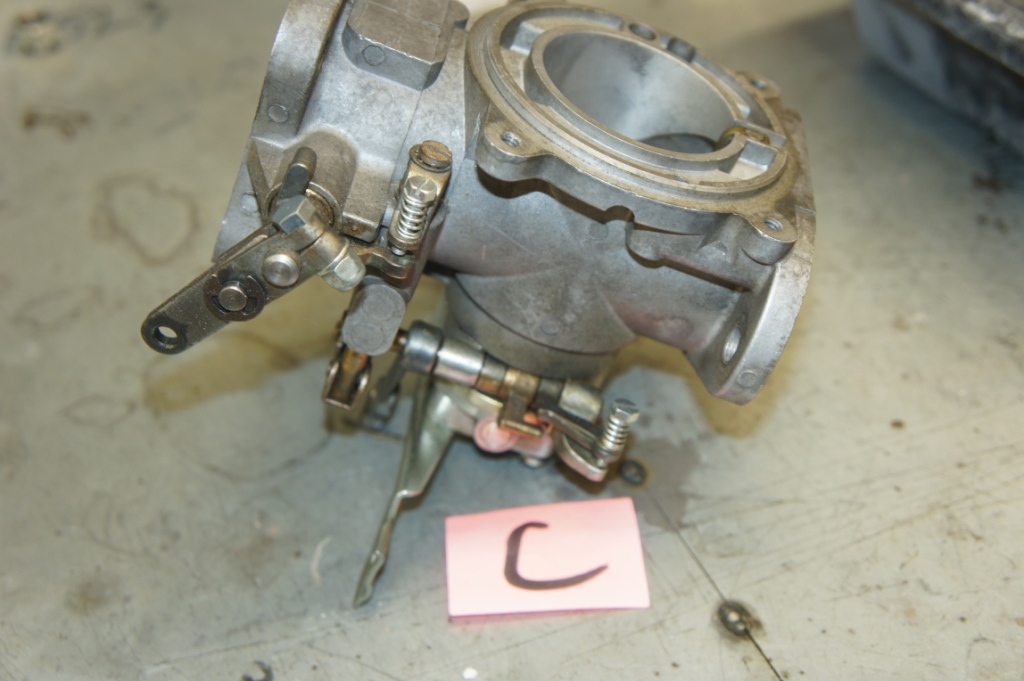

Emboldened by this, I've done all the blasting myself as usual - pressure set at 6 bar and done from some distance, very fine beads. The result is good enough for me and whilst it's not original straight-out-of-the-die, it's bright, clean, and smooth. The passage-ways in the SU are actually enormous in comparison with the motor-cycle stuff I usually restore, so my fears about blocking drillings are groundless.

I did solvent cleaning-bath first, hot wash with a Loctite de-greaser next, then blasting, cleaning-bath again, Loctite and hot-water again, lots of compressed air at all stages.

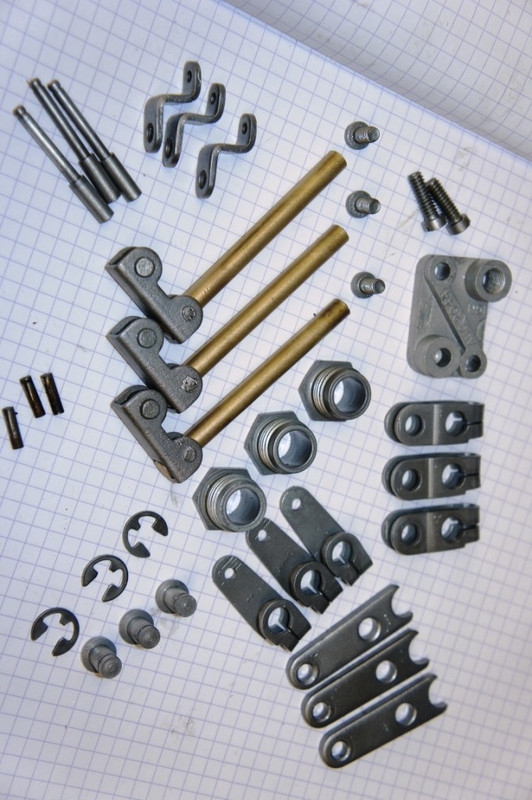

This of course with absolutely everything removed first (volume screw seal and washer, butterfly spindle seals, jet guide-block, piston-lifting pin, piston guide peg etc).

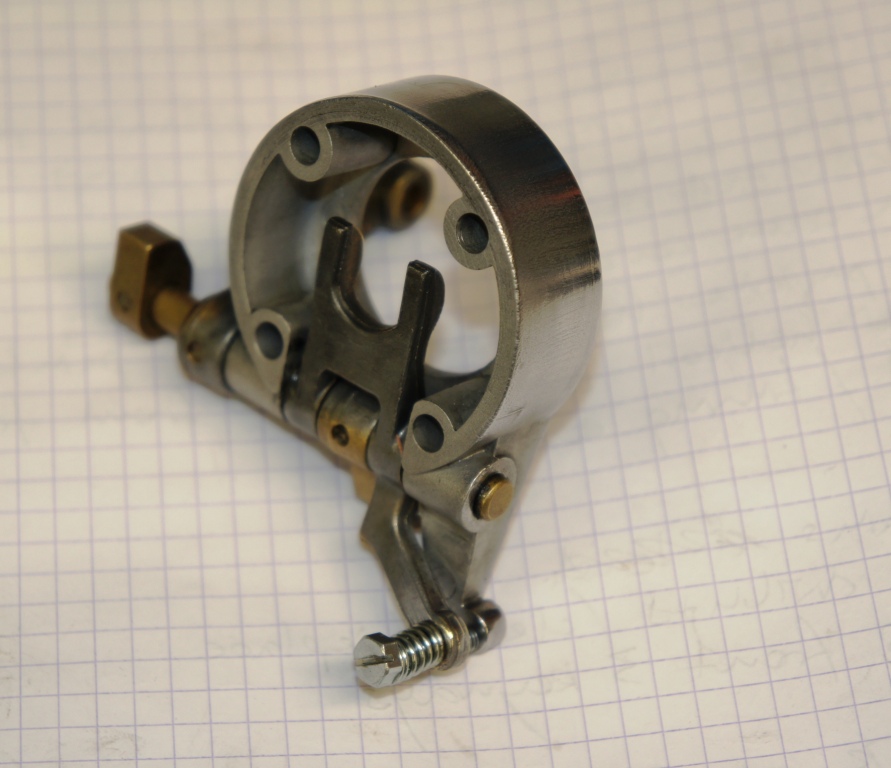

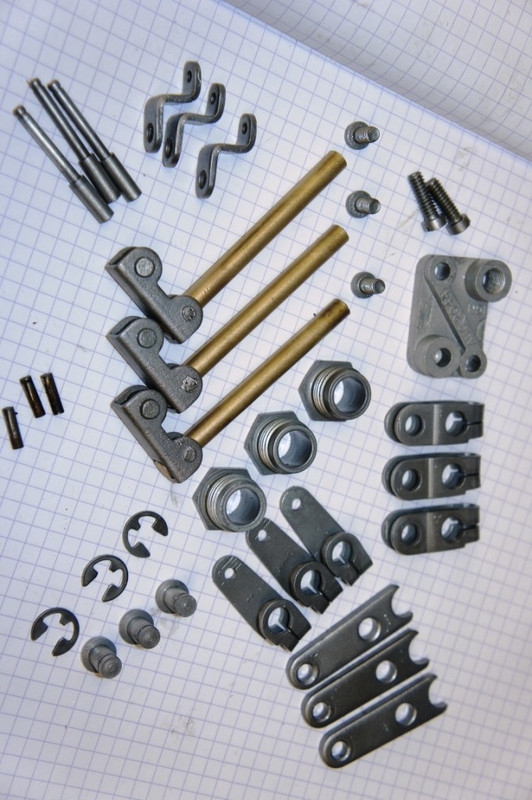

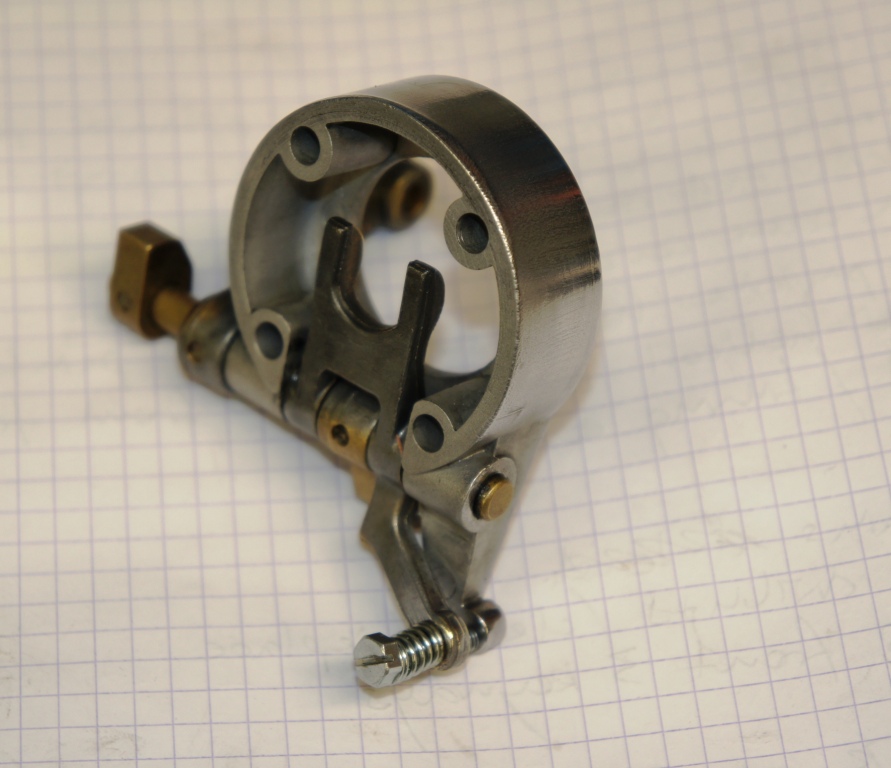

In order to clean and brighten up the choke-mechanism pivots, forks, cam etc I wanted to get one of the "taper pins" out and could find nothing on the Web - so FWIIW here are a couple of pictures that would have helped me - it wasn't immediately obvious which way they came out.

The pins are tapered and splined, and you need some sort of anvil so that the pin-punched blows on their ends are resisted very specifically on the opposite side ; they came out cleanly and easily.

Anvil from 6mm plate, held in the vice ; you need 4 hands.

and after blasting and polishing of the various bits were easily reassembled in reverse order, re-using the same pins.

Next job ; zinc-chromate galvanisation of all the attendant bits - probably not 100% original but some of the carb bits have already been over-polished by a PO so I can never aim for complete authenticity anyway.

The over-polishing refers to the float-chambers which I suspect shouldn't look like this ?

I am a professional carburetter restorer and have been at it for many years.

The first point to make is that if you are planning any sort of abrasive blasting the carb bodies must be completely stripped. Throttle spindles, disc, seals must all come out as well as the jet bearing nut. Seals and disc screws will have to be replaced with new upon reassembly.

There are several types of media which can be used.

1. Glass bead in compressed air gives a uniform finish which hides many imperfections but the resulant finish is not quite like the original out-of-the-die. The pressure can be adjusted to vary the finish.

2. Plastic bead in comp air using thermoset plastic gives a finish very like the original, but is only effective if the bodies are undamaged and have not already been glass beadblasted. Due to imperfections in the original material there may be patches of different colour appear.

3. Aqua blasting (glass bead in water) gives a finer finish than 1.

Before blasting the parts must be completely grease-free and dry of oil. After blasting the parts must be completely cleaned by flushing through with paraffin. I do this three times over to ensure no media is left, particularly in the hole where the idle screw sits, and the passage which follows it.

Emboldened by this, I've done all the blasting myself as usual - pressure set at 6 bar and done from some distance, very fine beads. The result is good enough for me and whilst it's not original straight-out-of-the-die, it's bright, clean, and smooth. The passage-ways in the SU are actually enormous in comparison with the motor-cycle stuff I usually restore, so my fears about blocking drillings are groundless.

I did solvent cleaning-bath first, hot wash with a Loctite de-greaser next, then blasting, cleaning-bath again, Loctite and hot-water again, lots of compressed air at all stages.

This of course with absolutely everything removed first (volume screw seal and washer, butterfly spindle seals, jet guide-block, piston-lifting pin, piston guide peg etc).

In order to clean and brighten up the choke-mechanism pivots, forks, cam etc I wanted to get one of the "taper pins" out and could find nothing on the Web - so FWIIW here are a couple of pictures that would have helped me - it wasn't immediately obvious which way they came out.

The pins are tapered and splined, and you need some sort of anvil so that the pin-punched blows on their ends are resisted very specifically on the opposite side ; they came out cleanly and easily.

Anvil from 6mm plate, held in the vice ; you need 4 hands.

and after blasting and polishing of the various bits were easily reassembled in reverse order, re-using the same pins.

Next job ; zinc-chromate galvanisation of all the attendant bits - probably not 100% original but some of the carb bits have already been over-polished by a PO so I can never aim for complete authenticity anyway.

The over-polishing refers to the float-chambers which I suspect shouldn't look like this ?

Last edited by rfs1957 on Tue Apr 24, 2018 6:12 pm, edited 1 time in total.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#19 Re: Restoring Carburettors - Tips, Methods ?

Hi Rory...what blast medium did you use..you mention fine bead but was it plastic or glass... Thanks.. Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#20 Re: Restoring Carburettors - Tips, Methods ?

Hi Steve, Glass beads of 106/212 granulometry.

I have other colleagues who use the same grade and grain for cleaning and brightening aluminium castings like me, our suppliers are in Lyon but these products will be identical across Europe at least.

Indeed I rang Gunson this morning, they still recommend their Honite 13 glass beads for this sort of application, it turns out that this is the same 106/212 calibre.

https://www.guyson.co.uk/aftersales/guy ... last-media

I was unaware that there was anything suitable made from plastic as all the plastic media I have seen is deliberately angular and seems to be aimed at paint-removal, I believe notably for the aeronautical industry ?

Gunson have a plastic media called Guyblast but do not consider it the best stuff for a gentle surface finish, and at almost FIVE times the price of glass beads it doesn't have much going for it.

https://www.guyson.co.uk/aftersales/guy ... last-media

If there's something better out there, I'm all ears.

I have other colleagues who use the same grade and grain for cleaning and brightening aluminium castings like me, our suppliers are in Lyon but these products will be identical across Europe at least.

Indeed I rang Gunson this morning, they still recommend their Honite 13 glass beads for this sort of application, it turns out that this is the same 106/212 calibre.

https://www.guyson.co.uk/aftersales/guy ... last-media

I was unaware that there was anything suitable made from plastic as all the plastic media I have seen is deliberately angular and seems to be aimed at paint-removal, I believe notably for the aeronautical industry ?

Gunson have a plastic media called Guyblast but do not consider it the best stuff for a gentle surface finish, and at almost FIVE times the price of glass beads it doesn't have much going for it.

https://www.guyson.co.uk/aftersales/guy ... last-media

If there's something better out there, I'm all ears.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |