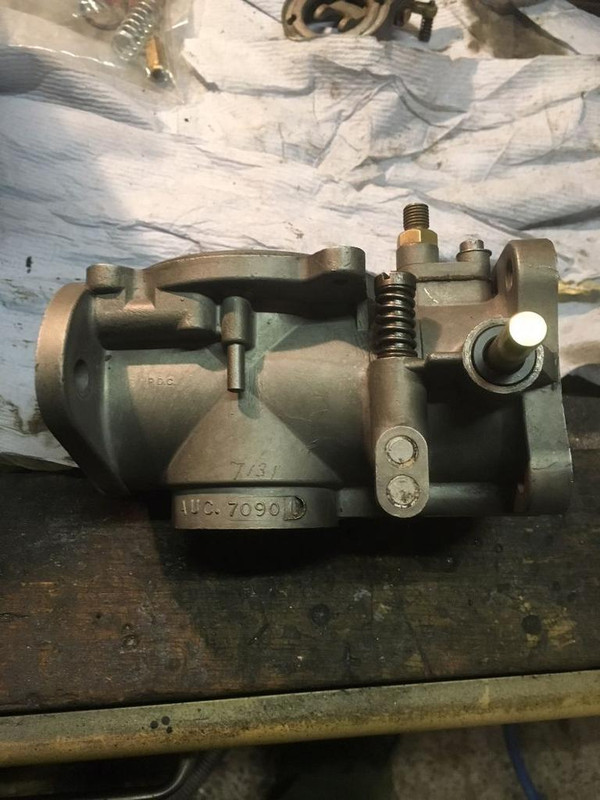

I've finally decided to rebuild the carbs after discovering that they are all leaking through their respective jet seals.

I have a question about the Burlen refurb kit and here's a photo of the parts in question:-

As you can see the new throttle spindle is longer than the old one and also lacks the hole for the throttle stop securing pin. I'm assuming that I'll have to drill this with the throttle shaft, stop and disc are temporarily fitted back in the carb body?

The throttle stop was originally secured by the fancy little screw lying beside it in the photo. I'm assuming the pin on the top left is the correct fixing.

Cheers

Alan