I would be the first to agree that it's "how it drives" that counts ; but I do not believe that 1 in a 1000 E-Type owners today have the time and ressources to conduct controlled, repeatable, multi-participant testing on caster-angle optimisation, never mind the inclination to do so, nor the experience to appraise what they're feeling.

And I am certainly not one of them.

Therefore it matters a lot to me to know that certain parameters on the Jaguar are set as the Factory thought correct.

Establishing that base-line requires a measuring system I can trust, and since Jag-chassis experts are thin on the ground around here, and probably in many areas around our Members' worlds, that means having your own tools.

IF a reputable and credible source of advice suggests that with modern tyres or w.h.y. the car works better with a

different setting, then I would STILL need that tool in order to achieve that.

With that in mind, and in the light of what has been written in previous posts, could I - as an aside - make this observation ?

As someone who bore the burden of being over-educated, and then spent almost the whole of his working life at the bench, so to speak, I am acutely aware of the two view-points that colour almost every Internet exchange - whatever the subject, whatever the Forum ; that of the "theorist" with no pratical experience, but lots of maths or w.h.y., and that of the "practician" who has no formal engineering, mathematical or metallurgical education, but "lots of time at the bench".

The one thing I have learned, and I would even qualify this as "a rare medical absolute", is that as a group, the former are far more prepared to listen to, and quicker to grasp the position of, the latter, than the reverse.

"Beware, I'm dangerous, I learn fast" is more often heard from one group than the other.

I even had a "specialist" and "experienced" author (responsible for some of the hog-wash that has passed into folk-lore regarding early S1 brake cylinders) retort that he was going to get his MIMechE friend to debunk my debunking because I was only an AMIMechE ......... but that was 2 years ago, not a peep since.

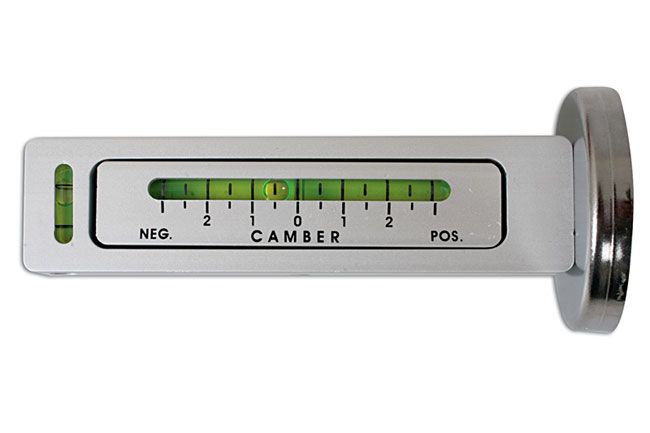

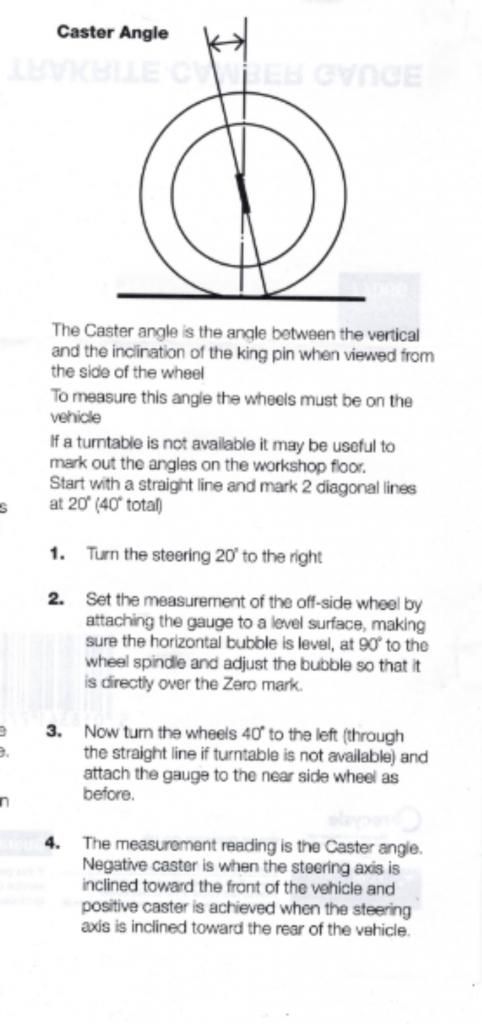

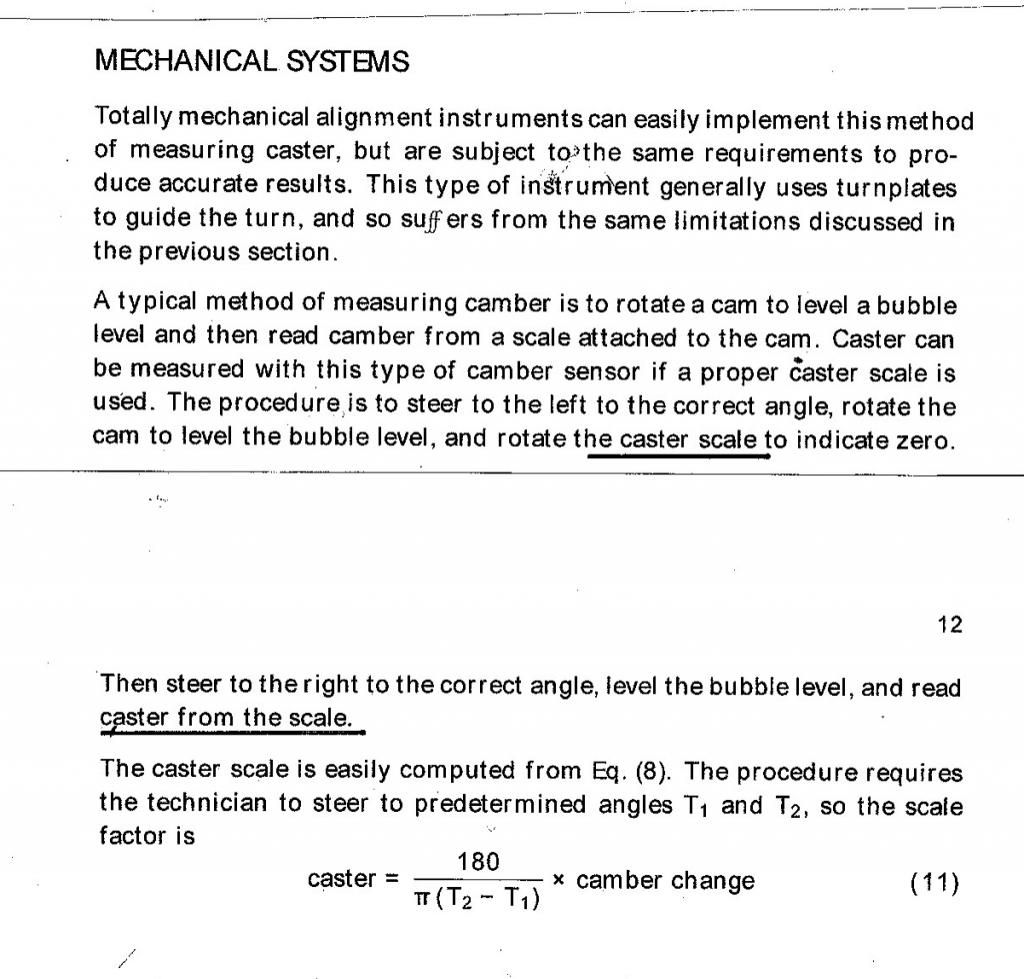

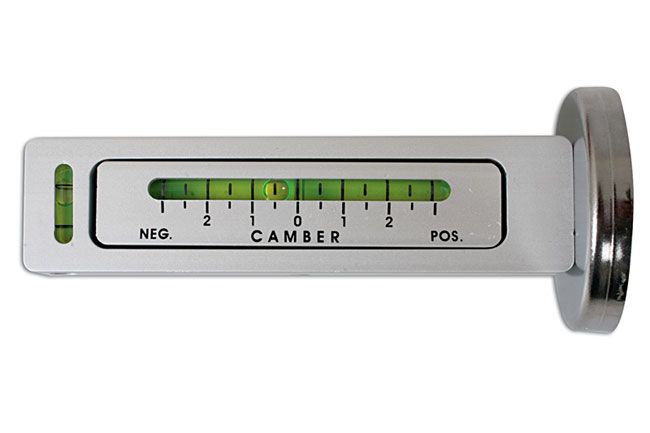

The key issue about the Trakrite guage is contained in the equation on page 12 ; could I suggest that if you can't cope with the maths, then - WADR - posting

it doesn't really matter anyway won't move the debate forward very much.

If you plug the 20?/20? swing into this equation, you find out that for every ? in camber change, you're actually seeing 1.4? of caster, and not the 1? Gunson claim.

The camber change ONLY EQUALS the caster change when (Pi x The Swing) = 180, which gives the swing as 57?.

REMEMBER the Trakrite has ONE scale that CLAIMS to do both ; but at 20?/20? it does nothing of the sort.

If you set your 3.8 by this method, instead of getting 2? you'll actually be getting 2.9?.

Sloppy thinking should be punishable by law.

I should get out more often.