Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

#1 Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

I am rebuilding a E type back axle for a client and have fitted a 2.88:1 XJS diff to replace the US supplied 3.54:1 diff. Having removed the completely different XJS inner fulcrum mountings and mastered shimming the bespoke E type inner fulcrum mountings onto the XJS diff as required to fit the E type cage, I was moving on to fit the lower wishbones. On inspecting the bearing tubes which are inside the needle roller bearings at each of the two wishbone pivot points, they showed bad wear and pitting from the needle roller bearings into the chrome surface of some of the original Jaguar bearing tubes. As the client was ordering various other parts from my recommended part supplier, I asked the client to order four new bearing tubes, part number C.17168/1.

These duly arrived - I had already decided to replace the 8 needle roller bearings with OEM items - as it would be bad practise to re-use the existing bearings if they had already caused that damage to the original bearing tubes. However, on inspection of the parts label, the replacement parts from my supplier has the "*" mark to signify "aftermarket" part and they are not chrome plated or do not appear to be hardened in any way. Already by putting them into the bearings I can already see scratches on their machined surfaces. They are not Stainless Steel and can be picked up by a magnet.

I phoned the supplier up this morning to see if I could get a better quality item, such as the "#" "OE" part, (they describe this marking as "the same quality, but not in the Jaguar box"), or better still, the part number with no suffix to show genuine Jaguar items. They confirmed that they can only supply the "aftermarket" part and I have just phoned three other major suppliers this morning who all can only supply the aftermarket item - with two kindly checking their stock to confirm they were not plated and just a machined surface.

As I cannot get the original part, I am concerned as they will only be moving a small rotational movement with a chromed needle roller bearing against a "normal" metal surface and the obvious damage they caused to the original chromed bearing surface tubes.

Has anyone experienced issues with these aftermarket bearing tubes, or am I worrying unnecessarily if they are well greased and will be fitted with new seals to try to prevent dirt on the rollers ?

regards,

Dave

These duly arrived - I had already decided to replace the 8 needle roller bearings with OEM items - as it would be bad practise to re-use the existing bearings if they had already caused that damage to the original bearing tubes. However, on inspection of the parts label, the replacement parts from my supplier has the "*" mark to signify "aftermarket" part and they are not chrome plated or do not appear to be hardened in any way. Already by putting them into the bearings I can already see scratches on their machined surfaces. They are not Stainless Steel and can be picked up by a magnet.

I phoned the supplier up this morning to see if I could get a better quality item, such as the "#" "OE" part, (they describe this marking as "the same quality, but not in the Jaguar box"), or better still, the part number with no suffix to show genuine Jaguar items. They confirmed that they can only supply the "aftermarket" part and I have just phoned three other major suppliers this morning who all can only supply the aftermarket item - with two kindly checking their stock to confirm they were not plated and just a machined surface.

As I cannot get the original part, I am concerned as they will only be moving a small rotational movement with a chromed needle roller bearing against a "normal" metal surface and the obvious damage they caused to the original chromed bearing surface tubes.

Has anyone experienced issues with these aftermarket bearing tubes, or am I worrying unnecessarily if they are well greased and will be fitted with new seals to try to prevent dirt on the rollers ?

regards,

Dave

Dave Rose

1967 Series 1 4.2 FHC

1967 Series 1 4.2 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Quattrofrank

- Posts: 316

- Joined: Fri Apr 04, 2014 4:17 pm

- Location: Norway, Oslo

#2

The wear should be taken up by the needle bearings.

I dont see any reason why the tubes should be hardened.

Btw I removed the needle bearings and fitted bronze bushings and did not use the tubes at all.

I dont see any reason why the tubes should be hardened.

Btw I removed the needle bearings and fitted bronze bushings and did not use the tubes at all.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Quattrofrank

- Posts: 316

- Joined: Fri Apr 04, 2014 4:17 pm

- Location: Norway, Oslo

#3

My answer was based on the outer tubes. I now see that you where asking about the inner tube.

My understanding is that the inner tube for the inner wishbone bearing is just to protect the fulcrum and needle bearings from dirt.

The tubes should have clearance against the fulcrum shaft.

My understanding is that the inner tube for the inner wishbone bearing is just to protect the fulcrum and needle bearings from dirt.

The tubes should have clearance against the fulcrum shaft.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#4

Hi Quattrofrank. thanks for your replies, but there must be pressure from the rollers in the bearings as the original chromed bearing tubes on which the rollers move over were worn and pitted.

Just for clarity, I am referring to a Series 2 E type axle and the "Bearing Tube", part number C.17168/1, through which the Fulcrum shaft passes with clearance. I am not referring to the Distance Tube, part number C17663/1, which fits between the two mounts on the Inner Fulcrum, which does protect the fulcrum shaft and needle bearings each side of it from dirt.

As the needle bearings are an interference fit into the wishbone ends, any rotation force must be transmitted through the bearing rollers onto the surface of the bearing tube as the bearing tubes do not move in the assembled pivot because they are clamped in postion by the inner and outer thrust washers each side of the bearing tube.

regards,

Dave

Just for clarity, I am referring to a Series 2 E type axle and the "Bearing Tube", part number C.17168/1, through which the Fulcrum shaft passes with clearance. I am not referring to the Distance Tube, part number C17663/1, which fits between the two mounts on the Inner Fulcrum, which does protect the fulcrum shaft and needle bearings each side of it from dirt.

As the needle bearings are an interference fit into the wishbone ends, any rotation force must be transmitted through the bearing rollers onto the surface of the bearing tube as the bearing tubes do not move in the assembled pivot because they are clamped in postion by the inner and outer thrust washers each side of the bearing tube.

regards,

Dave

Dave Rose

1967 Series 1 4.2 FHC

1967 Series 1 4.2 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Quattrofrank

- Posts: 316

- Joined: Fri Apr 04, 2014 4:17 pm

- Location: Norway, Oslo

#5

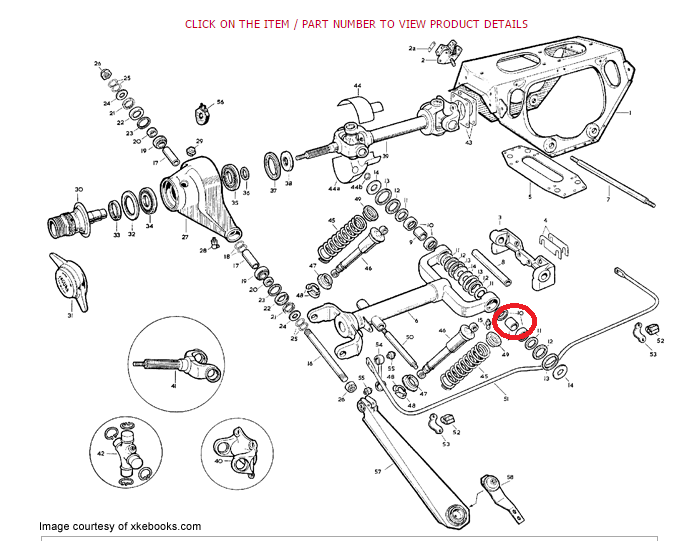

Ok, I now understand what you mean. You are talking about the tube that fits outside the shaft and inside the bearing?

The one inside the rear circle?

The one inside the rear circle?

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#6

Quattrofrank,

Yes, that's the one !!

Cheers,

Dave

Yes, that's the one !!

Cheers,

Dave

Dave Rose

1967 Series 1 4.2 FHC

1967 Series 1 4.2 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#7

Hi Dave Having worked on quite a few E Type rear ends - all of which display the same problem you note (inner bearing tube indented from the needle rollers), even with relatively low mileage, I came to the conclusion that the design is somewhat flawed, and years ago on at least three cars I substituted a bronze bushing for the needle roller bearing. Subsequent inspections revealed that they show no wear. There is such limited movement of the fulcrum on the bearing, combined with the very high load on the tiny bearing surface of the round needle that the type of wear you see must be inevitable. I don't make these "improvements" lightly - I'm not an engineer but a bushing as opposed to a needle roller seems seems a no brainer under the circumstances. I was concerned that the inner bearing would turn on the shaft and wear it but that seems not to happen. You used to be able to buy the bushing drilled and grooved to accept grease from the grease fitting, though it would be simple enough to make one up.

Probably not the answer you need but ............

Terry Sturgeon

Probably not the answer you need but ............

Terry Sturgeon

1967 E Type coupe

1968 E Type OTS

2007 XKR

1968 E Type OTS

2007 XKR

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#8 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hi All.....just thought i would bring this topic back to life....currently rebuilding up an IRS have purchased the inner fulcrum bearing tubes and the needle bearings but as mentioned in the above posts the outer surface of the tubes are just machined with a slight roughness to the surface....not smooth and chrome like as the originals which i cant use as they have some surface damage.....also the tubes are slightly loose in the needle rollers.....have you come across this.....did you find a good supplier.......as mentioned above some have replaced the needle rollers and tube with bushes.....is this a solution off the shelf or have to be machined.....thanks... Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#9 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hello Steve,

The Bronze rear suspension components, pictured below, are available from Classic Jaguar; the link to the site is also included below.

http://classicjaguar.com/cjparts/systembronze.php

The Top and Bottom two centre bushes are likely to be the replacement for the original needle roller system used as the inner fulcrum. I've not used, nor handled these parts, but it seems from the lube holes shown in the side view of the centre bottom components, that lubrication is being supplied to the shaft that passes though the whole assembly. This of course would be wrong, as the shaft, the original bushes and the washers either side of each arm of the swing arm should act as being a stationary component of the Rear Suspension Cradle. The bush shouldn't act as a bearing on the shaft, but as a sleeve on the shaft that is a bearing in the bore of the swing arm.

It is stated in an earlier Post that the original steel bearing sleeve for the roller bearing is chromed. I've not tested that, but I think that would be unlikely. Its common for hard chrome to be used as a wear surface applied to a soft substrate, not for a surface that is load bearing; hydraulic rams is one application that springs to mind.

Steel Bearing Sleeves are available for given Needle Roller Bearing sizes from bearing suppliers, but not in a length that can be used, or modified to suit the Jaguar swing arm application (all too short). When required, I make my own, using EN36A case hardening steel. After rough machining I have them double heat treated (case hardened followed by core refining). I've also made them using 4140, hardened to 45RC before machining and then nitrided after finish machining. I've had good results from both.

I think the Bronze Bush system would work well so long as the bush was held captive on the shaft (as is the original steel sleeve), and the OD of the bush acted as a bearing on either the bore of the Swing Arm (where the needle roller bearing are originally pressed in), or the smooth finish of a steel bush pressed into the bores of the swing arm. I would opt for steel bushes pressed into the swing arm because:

1. the original finish of the swing arm bores is not that great.

2. better to wear out a replaceable bush, than an expensive swing arm.

Regards,

Bill

The Bronze rear suspension components, pictured below, are available from Classic Jaguar; the link to the site is also included below.

http://classicjaguar.com/cjparts/systembronze.php

The Top and Bottom two centre bushes are likely to be the replacement for the original needle roller system used as the inner fulcrum. I've not used, nor handled these parts, but it seems from the lube holes shown in the side view of the centre bottom components, that lubrication is being supplied to the shaft that passes though the whole assembly. This of course would be wrong, as the shaft, the original bushes and the washers either side of each arm of the swing arm should act as being a stationary component of the Rear Suspension Cradle. The bush shouldn't act as a bearing on the shaft, but as a sleeve on the shaft that is a bearing in the bore of the swing arm.

It is stated in an earlier Post that the original steel bearing sleeve for the roller bearing is chromed. I've not tested that, but I think that would be unlikely. Its common for hard chrome to be used as a wear surface applied to a soft substrate, not for a surface that is load bearing; hydraulic rams is one application that springs to mind.

Steel Bearing Sleeves are available for given Needle Roller Bearing sizes from bearing suppliers, but not in a length that can be used, or modified to suit the Jaguar swing arm application (all too short). When required, I make my own, using EN36A case hardening steel. After rough machining I have them double heat treated (case hardened followed by core refining). I've also made them using 4140, hardened to 45RC before machining and then nitrided after finish machining. I've had good results from both.

I think the Bronze Bush system would work well so long as the bush was held captive on the shaft (as is the original steel sleeve), and the OD of the bush acted as a bearing on either the bore of the Swing Arm (where the needle roller bearing are originally pressed in), or the smooth finish of a steel bush pressed into the bores of the swing arm. I would opt for steel bushes pressed into the swing arm because:

1. the original finish of the swing arm bores is not that great.

2. better to wear out a replaceable bush, than an expensive swing arm.

Regards,

Bill

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#10 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

I don't get this. The original design works fine. Why try to replace it with a softer metal?

To me this is a solution in search of a problem.

To me this is a solution in search of a problem.

Andrew.

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#11 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Thanks for the replies so far.....the main problem im seeing at the moment is finding a supply manufactured to the original quality.......i dont have access locally or the skills to machine parts.....have measured the replacement tubes and they are smaller than the original.......i should imagin that most diy restorers are not even aware of the potential problem........whats frustrating is that i didnt buy these parts from one of the usuals but from an IRS rebuild service company.......Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#12 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Just a bit more info after searching for off the shelf parts from some of the bearing suppliers (Simply Bearings)

..the needle roller bearings are quite standard B-146..... they are an Imperial size....1&1/8 × 7/8 ×3/8.....various grades available.....the original tubes i have measured just with my digital caliper and converted to Imperial are outside dia 7/8 inside dia 5/8 the length is 1&9/64 (29.03mm)

Can find Carbon Chrome steel tubes with the correct int/ext diameters but not the exact length they are either shorter at 1&1/64in (25.65mm) or long at 1&25/64in (35.175mm)

So now need to work out if the length is critical..............note my imperial length calcs are just off the net so not spot on...so basically need a 29mm tube but can only find 25 or 35mm........Steve

..the needle roller bearings are quite standard B-146..... they are an Imperial size....1&1/8 × 7/8 ×3/8.....various grades available.....the original tubes i have measured just with my digital caliper and converted to Imperial are outside dia 7/8 inside dia 5/8 the length is 1&9/64 (29.03mm)

Can find Carbon Chrome steel tubes with the correct int/ext diameters but not the exact length they are either shorter at 1&1/64in (25.65mm) or long at 1&25/64in (35.175mm)

So now need to work out if the length is critical..............note my imperial length calcs are just off the net so not spot on...so basically need a 29mm tube but can only find 25 or 35mm........Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Doug Buchan

- Posts: 60

- Joined: Sun Apr 17, 2011 2:46 pm

- Location: Beach Haven, NJ

#13 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hi,

Pardon me for chiming in.

If you have an old piston gudgeon pin (wrist pin over here) laying around, check that for fit into the Torrington needle bearing. I believe it has the exact O.D of the factory bearing tube however the I.D. needs to be sized to accept the fulcrum shaft as well as having the length reduced. I believe I used one a long time ago and it worked out well.

Kind Regards,

Doug

Pardon me for chiming in.

If you have an old piston gudgeon pin (wrist pin over here) laying around, check that for fit into the Torrington needle bearing. I believe it has the exact O.D of the factory bearing tube however the I.D. needs to be sized to accept the fulcrum shaft as well as having the length reduced. I believe I used one a long time ago and it worked out well.

Kind Regards,

Doug

Doug

'67 ots

'67 ots

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#14 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hello Steve,

Yes, the length is critical to some extent. They need to be of a length so that when the nuts on the end of the shaft are tightened, both bearing bushes are clamped length ways via the long central spacer tube and the large diameter washers either side of each of the swing arm legs and effectively become larger diameters of the shaft. The needle roller bearings are a press fit in the swing arm (two per each leg) and therefore, move with the swing arm. To work correctly as a bearing, the needle roller bearing must rotate with the swing arm, relative to the bearing bush. Accordingly, the bush should not be able to rotate. Therefore, the length of bushes should be slightly greater than the width of each leg of the swing arm, into which the needle roller cages are pressed. You will be able to make the correct length bush out of the longer material you have found available.

Andrew Wrote:

If the Steel bush that pairs with the needle roller bearing is made from the correct material and heat treated to result in a hard surface for the bearing to run on, then there is nothing wrong with the original system. However, it’s not just a case of having a hard surface, as the substrate must be sufficiently hard to support the case (if a case hardening steel is used) and therefore resist brinelling, which is the main reason for the original system’s failure. My opinion is that through hardened bushes, hardened sufficiently to have the needles run on, may be too brittle (the wall thickness is small and may be subjected to shock loading). Accordingly, I like the use of EN36A for case hardening (used in high load bearing components such as gears), or 4140 pre-hardened and nitrided.

The idea of using a softer material such as bronze bearing alloy, (and some alloys can be quite hard, aluminium bronze for example), in the swing arm application, is that the needle roller bearings are eliminated and therefore, the requirement of a hard surface of the bush is also eliminated. The system using a bronze bearing would still require it to be a stationary part of the shaft that passes through the swing arm and that the swing arm rotates about it. As mentioned in my previous Post, to achieve this, the bronze bush would have to have an OD to act as a bearing in the bores of the swing arm legs, or use a hardened steel bush pressed into the swing arm legs and have the OD of the bronze bush run on the bore of the bush.

Regards,

Bill

Yes, the length is critical to some extent. They need to be of a length so that when the nuts on the end of the shaft are tightened, both bearing bushes are clamped length ways via the long central spacer tube and the large diameter washers either side of each of the swing arm legs and effectively become larger diameters of the shaft. The needle roller bearings are a press fit in the swing arm (two per each leg) and therefore, move with the swing arm. To work correctly as a bearing, the needle roller bearing must rotate with the swing arm, relative to the bearing bush. Accordingly, the bush should not be able to rotate. Therefore, the length of bushes should be slightly greater than the width of each leg of the swing arm, into which the needle roller cages are pressed. You will be able to make the correct length bush out of the longer material you have found available.

Andrew Wrote:

Hello Andrew,I don't get this. The original design works fine. Why try to replace it with a softer metal?

To me this is a solution in search of a problem.

If the Steel bush that pairs with the needle roller bearing is made from the correct material and heat treated to result in a hard surface for the bearing to run on, then there is nothing wrong with the original system. However, it’s not just a case of having a hard surface, as the substrate must be sufficiently hard to support the case (if a case hardening steel is used) and therefore resist brinelling, which is the main reason for the original system’s failure. My opinion is that through hardened bushes, hardened sufficiently to have the needles run on, may be too brittle (the wall thickness is small and may be subjected to shock loading). Accordingly, I like the use of EN36A for case hardening (used in high load bearing components such as gears), or 4140 pre-hardened and nitrided.

The idea of using a softer material such as bronze bearing alloy, (and some alloys can be quite hard, aluminium bronze for example), in the swing arm application, is that the needle roller bearings are eliminated and therefore, the requirement of a hard surface of the bush is also eliminated. The system using a bronze bearing would still require it to be a stationary part of the shaft that passes through the swing arm and that the swing arm rotates about it. As mentioned in my previous Post, to achieve this, the bronze bush would have to have an OD to act as a bearing in the bores of the swing arm legs, or use a hardened steel bush pressed into the swing arm legs and have the OD of the bronze bush run on the bore of the bush.

Regards,

Bill

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#15 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hi Bill...thanks for taking the time with your explanation.....i got sidetraked looking for a better quality tube and hadn't put in enough time to work out the length.....have a great new year.... Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#16 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hello Steve,

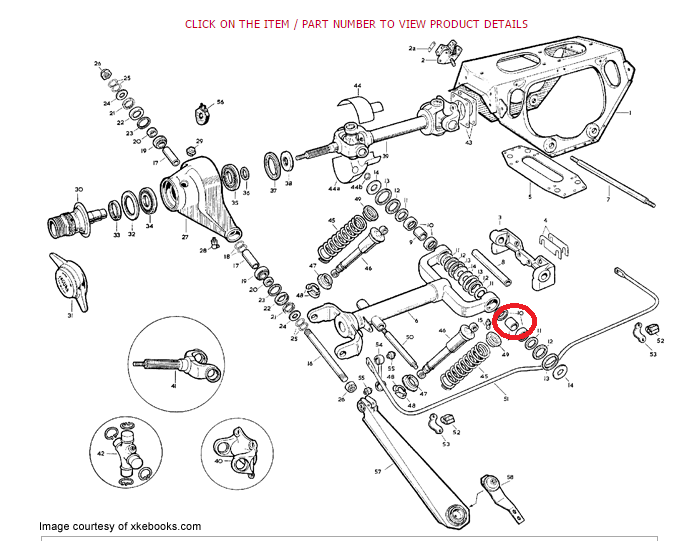

To be entirely accurate, the Needle Roller Bushes are caught tight between the inside surface of the Rear Suspension Cradle, two Large Thrust Washers (one either side of each leg of the Swing Arm) and the Fulcrum Bracket that is attached to the differential. A long support spacer tube is a close fit between the two lugs of the Fulcrum Bracket.

1. The dimension over the two Small Thrust Washers, as shown in the attached picture is 28.9mm

2. The length of the Needle Roller Bearing Bush is 29.05mm

Given the above dimensions, its clear that the Large Thrust Washers will contact the end of the Bush with an overall clearance of 0.15mm (0.006") between the faces of the Small and Large Thrust Washers and will hold the Bush tight between the Rear Suspension Cradle and the lugs of the Fulcrum Bracket when the nuts of the Fulcrum Shaft are tightened.

All the best for the New Year.

Best regards,

Bill

To be entirely accurate, the Needle Roller Bushes are caught tight between the inside surface of the Rear Suspension Cradle, two Large Thrust Washers (one either side of each leg of the Swing Arm) and the Fulcrum Bracket that is attached to the differential. A long support spacer tube is a close fit between the two lugs of the Fulcrum Bracket.

1. The dimension over the two Small Thrust Washers, as shown in the attached picture is 28.9mm

2. The length of the Needle Roller Bearing Bush is 29.05mm

Given the above dimensions, its clear that the Large Thrust Washers will contact the end of the Bush with an overall clearance of 0.15mm (0.006") between the faces of the Small and Large Thrust Washers and will hold the Bush tight between the Rear Suspension Cradle and the lugs of the Fulcrum Bracket when the nuts of the Fulcrum Shaft are tightened.

All the best for the New Year.

Best regards,

Bill

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#17 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Hi Steve,

As Bill says, the length is critical. Too short and the cage will clamp up on the wishbones, too long and you will get forward and backwards movement on the wishbones as well as the chance of the seals dropping out of place.

A little tip for building it up when you finally get the right ones is to gently spread the cage with a sash clamp to allow you to slot the thrust washers and seals in. A bit of sticky grease also helps hold them in place.

Hope you get it sorted,

Simon

As Bill says, the length is critical. Too short and the cage will clamp up on the wishbones, too long and you will get forward and backwards movement on the wishbones as well as the chance of the seals dropping out of place.

A little tip for building it up when you finally get the right ones is to gently spread the cage with a sash clamp to allow you to slot the thrust washers and seals in. A bit of sticky grease also helps hold them in place.

Hope you get it sorted,

Simon

Simon

1969 S2 OTS

1969 S2 OTS

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#18 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Just been having a much closer look at this.....its also crucial to have the thrust washers that fit over the tubes the correct thickness...and also the machined surface of the wishbone clean...anyone useing something like Por15 to paint the wishbones and get it on the machined surface will create extra thickness......Still need to find a supplier of correct spacer/tube.....Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#19 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

I just ran a good file across an old set of these tubes and it didn't mark what was clearly a hardened surface. I've worked with hard chrome plated telescopic bike forks for decades and I don't *think* these little suspension tubes are plated - just ground and polished. The brinell markings are the norm after several decades of 'out of sight, out of mind' neglect but I've never noticed flaking chrome at the edges of the damaged surface.44DHR wrote: ↑Thu Sep 03, 2015 10:32 am...On inspecting the bearing tubes which are inside the needle roller bearings at each of the two wishbone pivot points, they showed bad wear and pitting from the needle roller bearings into the chrome surface of some of the original Jaguar bearing tubes...

..they are not chrome plated or do not appear to be hardened in any way. Already by putting them into the bearings I can already see scratches on their machined surfaces. They are not Stainless St - ....they were not plated and just a machined surface..., I am concerned as they will only be moving a small rotational movement with a chromed needle roller bearing against a "normal" metal surface and the obvious damage they caused to the original chromed bearing surface tubes.

Has anyone experienced issues with these aftermarket bearing tubes, or am I worrying unnecessarily if they are well greased and will be fitted with new seals to try to prevent dirt on the rollers ?

The miles most people do and regular squirts from the grease gun should ensure they last for several more decades.

There is a good case for switching to bushes, provided they are drilled eccentric. It's about the easiest way to get significant negative camber once all the shims are out. Handy for slalom/autocross competition.

Last edited by PeterCrespin on Thu Jan 04, 2018 10:56 am, edited 1 time in total.

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#20 Re: Rear Inner Fulcrum Shaft Bearing Tubes - Material ?

Pete,

I agree with you that it is unlikely these tubes were originally chromed, but I was incorrectly using that term to highlight the finish of the “original” tubes compared to the quality of the finish currently on offer by all the well known parts suppliers today.

It just seemed from an engineering perspective that it was unfortunate to be fitting new high quality machined and plated needle bearings that they would be immediately contacting a surface finish on the new tubes which already had a poor scratched surface. Athough they had limited rotational movement, just seemed wrong. If I am rebuilding something, I want to put it back together in it’s best possible finish and condition. I also work on my bikes here and it’s a bit like fitting a new chain and not changing both sprockets, even if they look alright and will do the job.

Again, I agree with you that even these poor finished offerings from the usuals today will last a very long time with clean grease and regular attention in the application they are doing. I was really highlighting that even these tiny items cannot be supplied with a better surface finish as I for one would be be prepared to pay a higher price to get a better quality item - especially on such small items - than settle for a poorer quality item even though I know they will do the job. It just hurts me to fit parts I personally don’t like the look of.

At the risk of going off on a tangent to this thread, the idea of eccentric bushes for altering the rear camber angle would presumably need some form of locking mechanism to maintain the bushes in their rotated position to move the wishbone pivots outward, if the fulcrum shafts are maintained in their original positions in the rear mounting cage holes ?

Regards,

Dave

I agree with you that it is unlikely these tubes were originally chromed, but I was incorrectly using that term to highlight the finish of the “original” tubes compared to the quality of the finish currently on offer by all the well known parts suppliers today.

It just seemed from an engineering perspective that it was unfortunate to be fitting new high quality machined and plated needle bearings that they would be immediately contacting a surface finish on the new tubes which already had a poor scratched surface. Athough they had limited rotational movement, just seemed wrong. If I am rebuilding something, I want to put it back together in it’s best possible finish and condition. I also work on my bikes here and it’s a bit like fitting a new chain and not changing both sprockets, even if they look alright and will do the job.

Again, I agree with you that even these poor finished offerings from the usuals today will last a very long time with clean grease and regular attention in the application they are doing. I was really highlighting that even these tiny items cannot be supplied with a better surface finish as I for one would be be prepared to pay a higher price to get a better quality item - especially on such small items - than settle for a poorer quality item even though I know they will do the job. It just hurts me to fit parts I personally don’t like the look of.

At the risk of going off on a tangent to this thread, the idea of eccentric bushes for altering the rear camber angle would presumably need some form of locking mechanism to maintain the bushes in their rotated position to move the wishbone pivots outward, if the fulcrum shafts are maintained in their original positions in the rear mounting cage holes ?

Regards,

Dave

Dave Rose

1967 Series 1 4.2 FHC

1967 Series 1 4.2 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |