Talk about the E-Type Series 1

-

Topic author

Philk

- Posts: 711

- Joined: Wed Dec 07, 2016 7:48 am

Post

by Philk » Sun May 27, 2018 9:38 pm

So, having finally got the master cylinder replaced and the clutch now fully working, I have noticed an occasional high pitched squeal (similar to brake squeal) when the clutch is depressed (it stops by the time the clutch is fully depressed) and is worse when the car is hot. The engine has been fully rebuilt (500 miles driven since), the clutch replaced at that time and the gearbox overhauled. I am assuming the clutch release bearing was replaced at the same time.

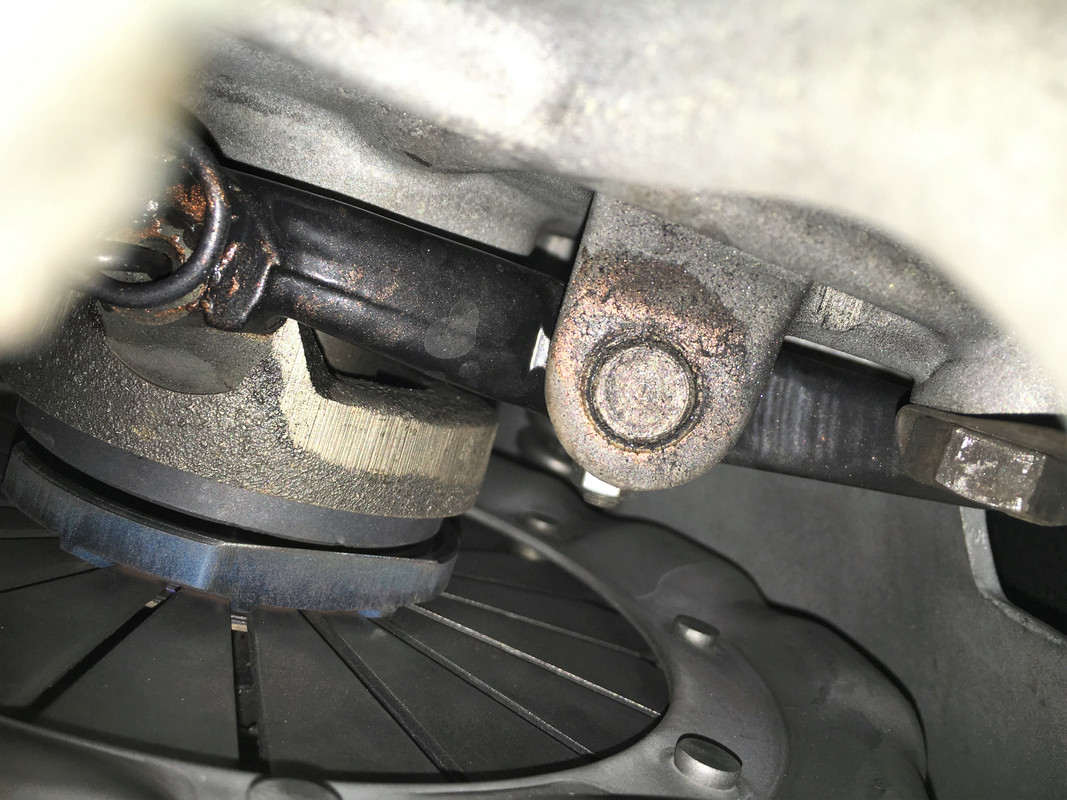

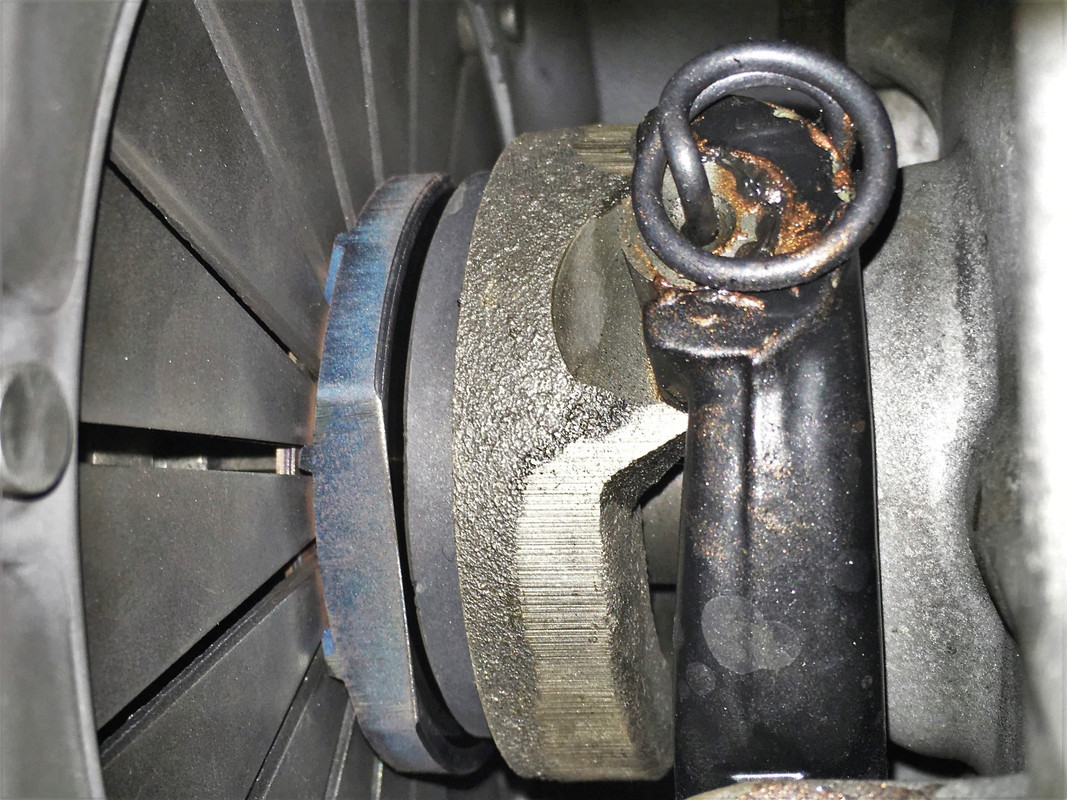

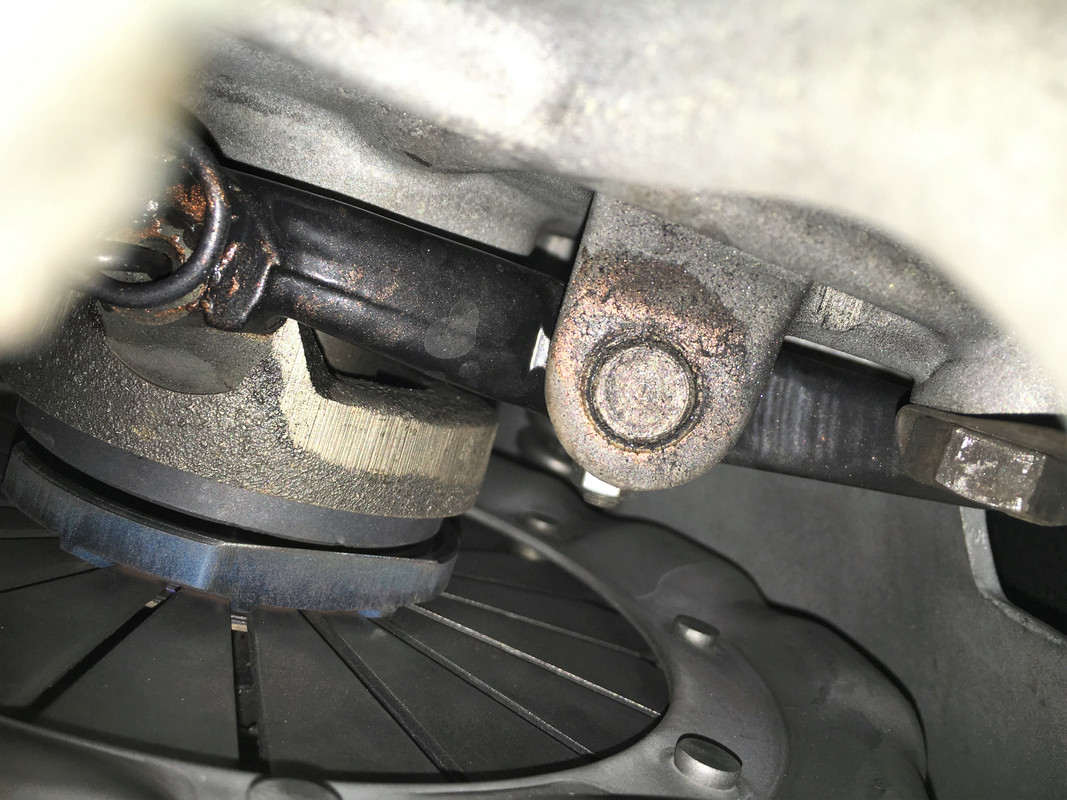

I have managed to take some photos through the inspection hole of the bell housing (am quite impressed at the iPhone for this). This appears to show the release bearing is at an angle to the release ring. Is this normal and could this account for the noise? The operation of the clutch is beyond my own technical understanding so would be grateful for the thoughts of those far more learned than me!

Many thanks!

Last edited by

Philk on Mon May 28, 2018 2:40 pm, edited 3 times in total.

Phil

1964 S1 3.8 OTS

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

Post

by christopher storey » Mon May 28, 2018 10:43 am

Humph ! There is no way of telling whether this is serious at this stage . Amongst other things, it rather depends whether the release bearing is a carbon type or a ball/roller bearing type ( I have seen both, but others may know when or if there was a changeover point ) . What I would do is 1.report the matter to the restorer and check what was fitted on the rebuild , and 2. Continue to drive and see whether it settles - it may just be that the new driven plate is settling in to the flywheel

-

Topic author

Philk

- Posts: 711

- Joined: Wed Dec 07, 2016 7:48 am

Post

by Philk » Mon May 28, 2018 10:57 am

christopher storey wrote: ↑Mon May 28, 2018 10:43 am

Humph ! There is no way of telling whether this is serious at this stage . Amongst other things, it rather depends whether the release bearing is a carbon type or a ball/roller bearing type ( I have seen both, but others may know when or if there was a changeover point ) . What I would do is 1.report the matter to the restorer and check what was fitted on the rebuild , and 2. Continue to drive and see whether it settles - it may just be that the new driven plate is settling in to the flywheel

Hi Christopher

I updated the post with some photos whilst you were posting your reply. I believe it is a carbon type release bearing in terms of what the mechanic has mentioned to us (when we were having the issues with the master cylinder).

Regards

Phil

Phil

1964 S1 3.8 OTS

-

Moeregaard

- Posts: 763

- Joined: Thu Mar 13, 2008 7:23 pm

- Location: Thousand Oaks, California

Post

by Moeregaard » Mon May 28, 2018 2:48 pm

It sounds as if your pilot-shaft bushing is galling on the input shaft. I've seen this on E-Types that are driven very infrequently, or have been dormant for a very long time. It can also occur when some "mechanic" has applied grease to the input shaft prior to mating the engine and gearbox. Grease quickly clogs the pores of the oilite bushing in the crankshaft and the squealing begins not long after, due to galling between the pilot shaft and bushing. In extreme cases shifting gears can become difficult.

Remove the old bushing by tapping it (I forget which thread size), screwing in a bolt, and levering the whole mess out. Soak the new bushing overnight in oil, and drive it home using a wooden dowel and soft-faced hammer. It should go in easily.

Another problem that can cause difficult shifting on E-Types that are not driven frequently, is the clutch driven plate galling on the input shaft splines, due to corrosion. Using a small wire brush, clean all of the rusty stuff from the splines and apply a very small amount of anti-seize compound to the splines, work the driven plate back and forth on the splines, wiping up the excess goo before reinstalling the clutch.

Mark (Moe) Shipley

Former owner '66FHC, #1E32208

Former owner '65FHC, #1E30036

Planning on getting E-Type No. 3 as soon as possible....

-

mach2andy

- Posts: 298

- Joined: Wed Jun 21, 2017 9:31 am

Post

by mach2andy » Mon May 28, 2018 3:26 pm

I agree with Moe. I had the same issue on my Corvette. The noise is most likely the pilot bush located in the end of the crankshaft particularly as you say that the noise disappears when the clutch is fully engaged. At that point there is no relative movement between the gearbox input shaft [which sits inside the bush which is in the end of the crankshaft] and the crankshaft itself as they are locked together hence the noise disappears. I assume that the repairers replaced the bush when they changed your clutch, and it's probably still a bit tight. It will eventually wear in, and the noise will disappear. There is an easier way to remove the spigot bearing than Moe describes, but as you won't be doing the job, I won't bother to detail it.

Andy

1970 S2 FHC

1965 SB Corvette Ragtop

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

Post

by christopher storey » Mon May 28, 2018 6:34 pm

I think mach2andy has misunderstood your initial post, in that the noise disappears by the time the clutch is fully disengaged, at which time there is much more relative motion of pilot bush ( crankshaft rpm ) and first motion shaft, particularly with the car at a low road speed and/or in a high gear . This tends to militate against the pilot bush being the source of the noise . It would be interesting to see a pic taken when there is someone lightly pressing the pedal so that the carbon thrust was fully engaged with the clutch cover - at that point the carbon thrust should have swivelled on its gimbals so that its entire surface is flat against the diaphragm release of the clutch cover , but before it is pressing sufficiently to operate the diaphragm. If it is flat , then I don't think you have much to worry about as far as the thrust is concerned

-

Topic author

Philk

- Posts: 711

- Joined: Wed Dec 07, 2016 7:48 am

Post

by Philk » Mon May 28, 2018 8:59 pm

Thank you all for the responses. As per my original post, there is no "squealing" noise when the clutch is either fully engaged (i.e. clutch pedal depressed) or when it is not engaged. The noise only briefly occurs as the clutch is being depressed

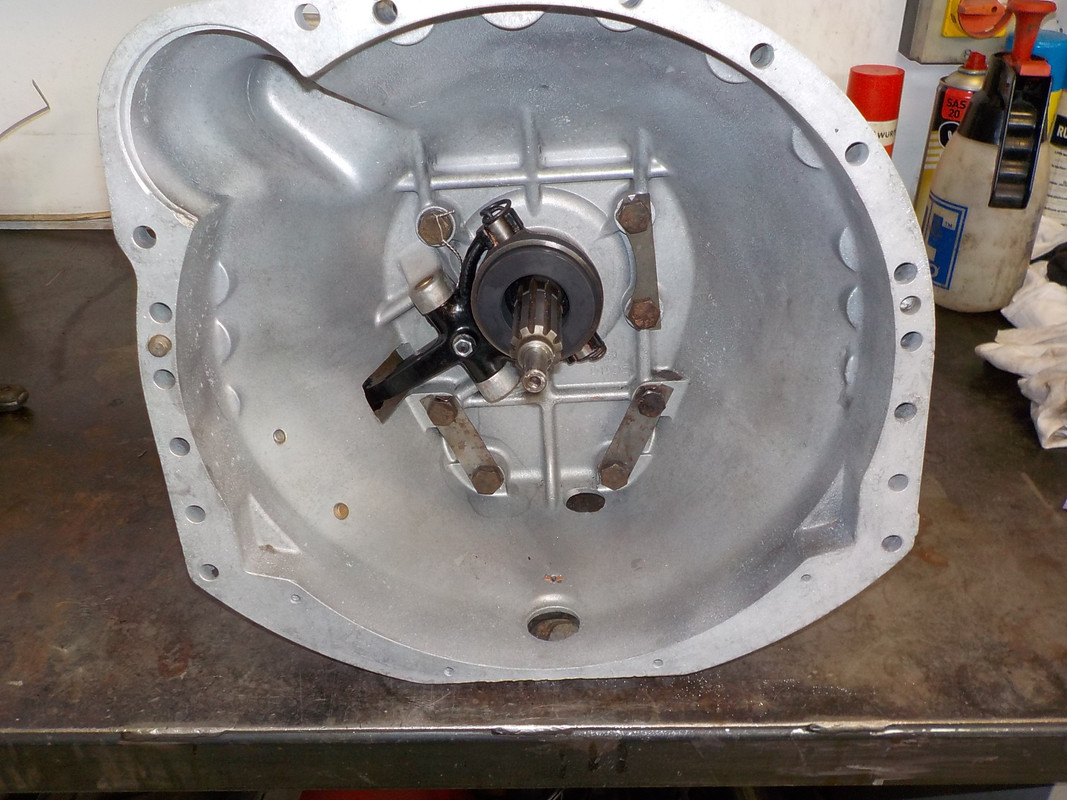

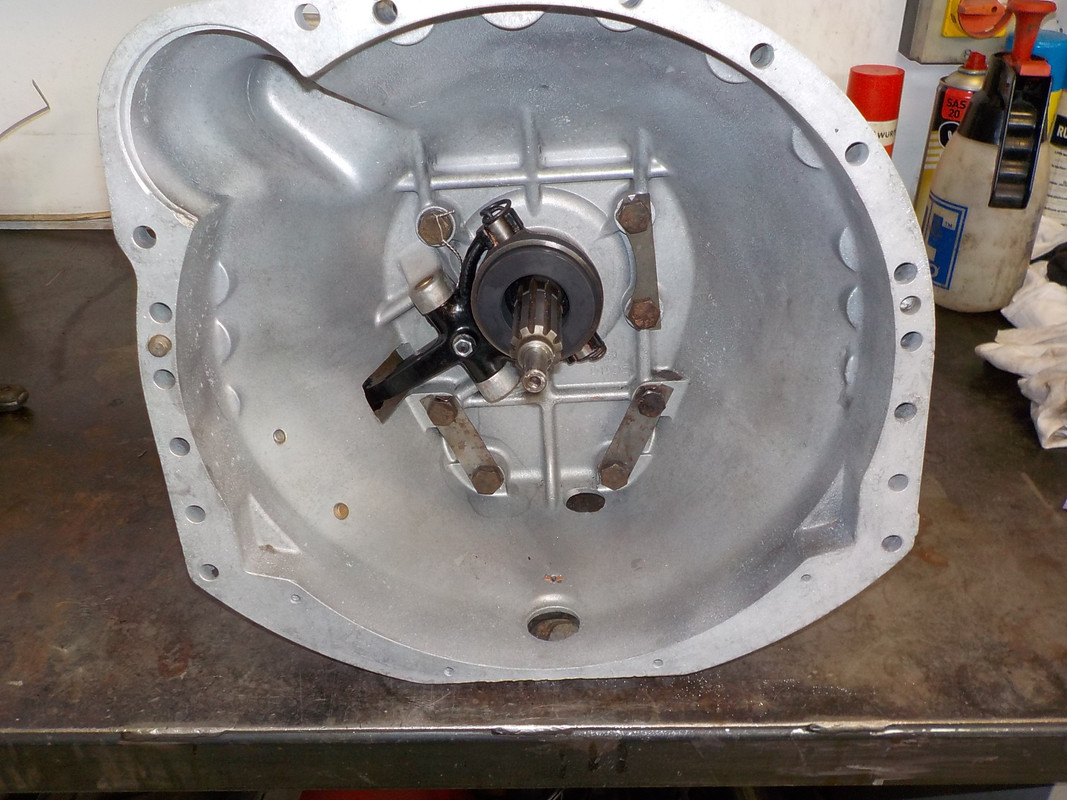

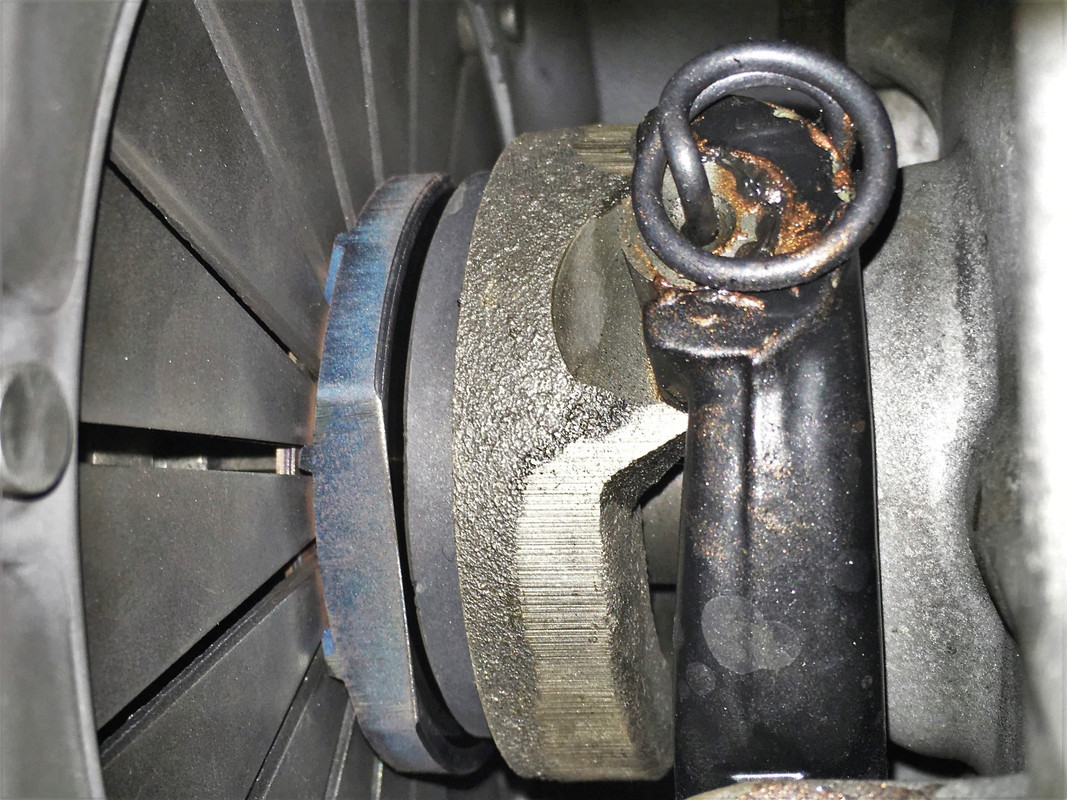

With the engine not running, I got someone to fully engage the clutch whilst I took some further pictures through the bell housing. What is interesting is that the release bearing has not rotated within the gimbals to lay flat against the "receiving" clutch ring. I'm therefore wondering whether this is responsible for the noise and whether there is anything that can be done about this. I've attached a photo below of the position when the clutch pedal is fully depressed. I've also attached a photo of the bell housing with the new release bearing fitted during the restoration.

Phil

1964 S1 3.8 OTS

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

Post

by christopher storey » Tue May 29, 2018 8:59 am

I don't quite know what to make of this . The 2 sets of photos are with the release thrust rotated through 180 degrees between each set, and there appears to be some disparity between them , with the first set having rather more metal in the thrust carrier, than in the second set where the carrier is more heavily "cut-away". The disparity strikes me as very odd . It is almost as though the shank of the carrier is not fully engaged in the fork on one side ( and I suppose this could account for the assymetry between thrust and diaphragm ) . I think you should show this to the rebuilder of engine/box and ask for comments . Did they supply the thrust bearing ?

-

Topic author

Philk

- Posts: 711

- Joined: Wed Dec 07, 2016 7:48 am

Post

by Philk » Tue May 29, 2018 10:38 am

christopher storey wrote: ↑Tue May 29, 2018 8:59 am

I don't quite know what to make of this . The 2 sets of photos are with the release thrust rotated through 180 degrees between each set, and there appears to be some disparity between them , with the first set having rather more metal in the thrust carrier, than in the second set where the carrier is more heavily "cut-away". The disparity strikes me as very odd . It is almost as though the shank of the carrier is not fully engaged in the fork on one side ( and I suppose this could account for the assymetry between thrust and diaphragm ) . I think you should show this to the rebuilder of engine/box and ask for comments . Did they supply the thrust bearing ?

Having looked closely at the photos again (I have a two screen set up and have had the clutch engaged/disengaged photos on different screens), I can see that the shank is actually rotating in the bottom gimbal on the fork. Whilst we cannot see the top fork (given the photo has been taken looking vertically upwards through the inspection hole at the bottom of the bell housing), I would be astonished if it was not seated properly in the top gimbal (the mechanic is v experienced at the restorers). The before and after photos were taken without the engine running so they simply show the lever in its disengaged position (with the clutch pedal not depressed) and then again with the clutch pedal depressed (i.e. with the lever pushing down on the centre point on the diaphragm).

I took another photograph last night after the car had been for a run. This perhaps makes more sense in terms of perspective (with the diaphragm on the left). From this angle, things don't look too bad. I may just ask the restorer to explore this all in more depth when the car next goes there. Unfortunately, my mechanical knowledge is not deep in this area.

Phil

1964 S1 3.8 OTS

-

rossbraithwaite

- Posts: 173

- Joined: Mon Jan 24, 2011 8:27 pm

- Location: The National Forest

Post

by rossbraithwaite » Tue May 29, 2018 12:37 pm

Your description of the symptoms sounds very familiar from my own car. It has been like that for at least five years and it gets driven quite regularly. All I can say is that the noise hasn't got any worse in that time and other than being (another) annoying noise there are no other issues.

'67 S1.5 FHC, manual, maroon with black interior. Originally exported to Arizona but 'repatriated' in '89. Since converted to RHD and triple SUs.

-

Topic author

Philk

- Posts: 711

- Joined: Wed Dec 07, 2016 7:48 am

Post

by Philk » Thu May 31, 2018 6:47 am

rossbraithwaite wrote: ↑Tue May 29, 2018 12:37 pm

Your description of the symptoms sounds very familiar from my own car. It has been like that for at least five years and it gets driven quite regularly. All I can say is that the noise hasn't got any worse in that time and other than being (another) annoying noise there are no other issues.

I had a useful conversation with the restorer earlier in the week. We are going to monitor things as all the new and overhauled parts are currently settling in. Since there is no adjustability on the fork or the gimbals given their fixed position, there may be little that can be done if the noise is simply coming from the new carbon bearing. Over the years, they have seen a number of S1 release bearings that are more worn on one side than the other and the initial angle of attack on the diaphragm plate could be the cause. As the bearing slowly beds in, a greater surface area will make contact and therefore give a more even “push”. As there are no other symptoms and the noise does cease as the clutch continues to depress it could also be dust and fibres from the new friction plate. Will continue to monitor.

Phil

1964 S1 3.8 OTS