Steering Rack fail safes

#21

I do appreciate the help Peter, but to be honest I have been doing this for a very long time and don't appreciate the patronising posts!! I am sure its just your way, but to be honest, I just wanted some guidance from someone who had done the job before, not a lecture on reading my manual!

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#22

I enjoy Pete's lectures as I invariably learn something even if it is only about desmodronic valves or some such. Having gone back and re-read this entire thread I don't think it comes across as "patronising", just a strong case for RTFM. As with any post, if you open the door don't be surprised if people walk through it! :)

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#23

Yes well, as you say if you open the door......

However, without the benefit of either a suitable schematic in the manual or the parts book, or having failed to take enough note of the dismantling ( that's where the real problem lies!) it is NOT clear in the manual how the various nuts bolts, washers, spacers fit. Added to that, there is no explanation of why there would be a different set up on each side of the rack, it was a clear case for asking the question. All it needed was a simple explanation which I did eventually get. I still maintain that without the benefit of making a note of how it was pulled down, the books DO NOT detail how it goes back together. Simples! Anwyay, I am sure Peter will not have taken offence...as they say, if you live by the sword, then you die by the sword!

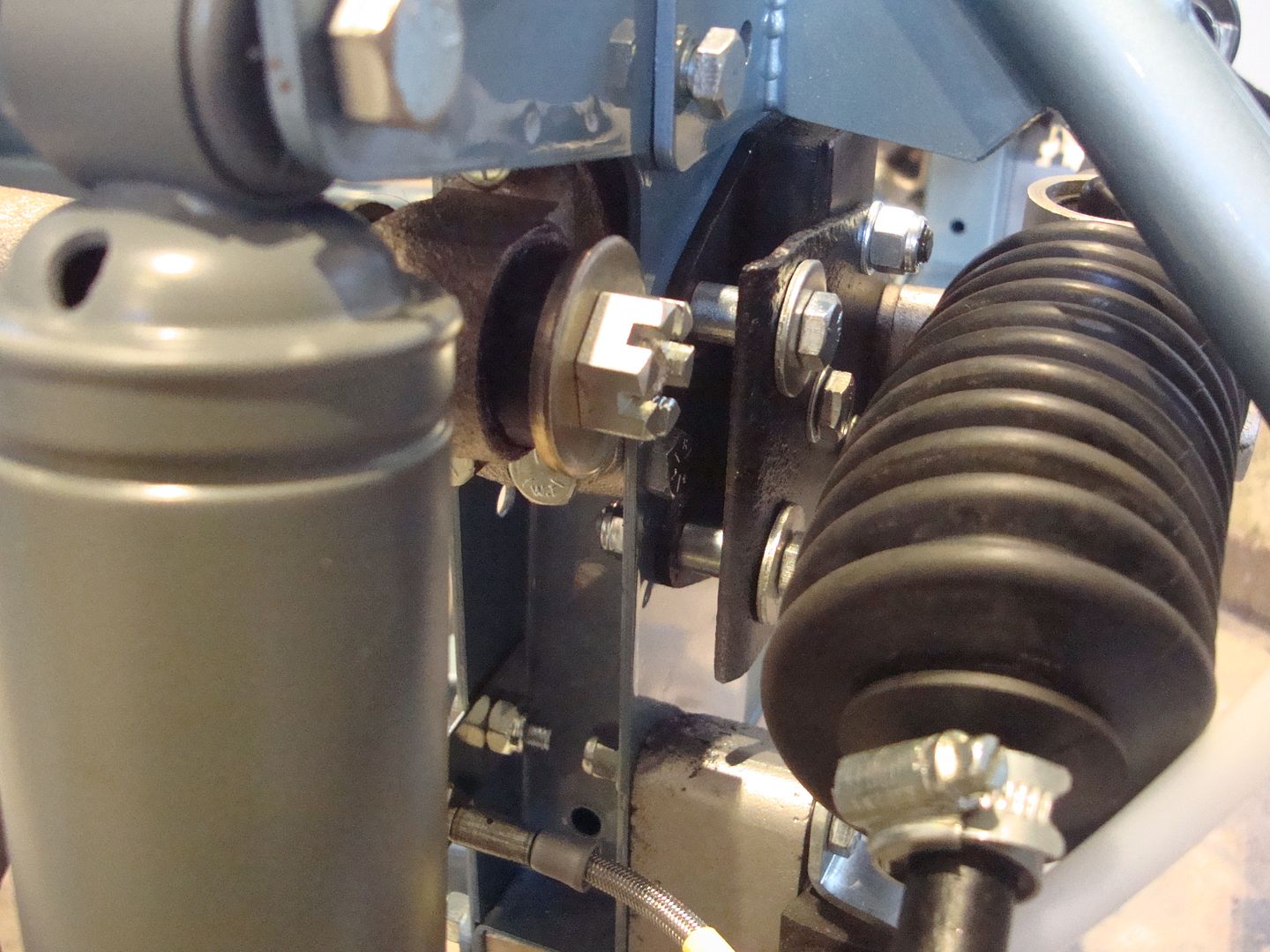

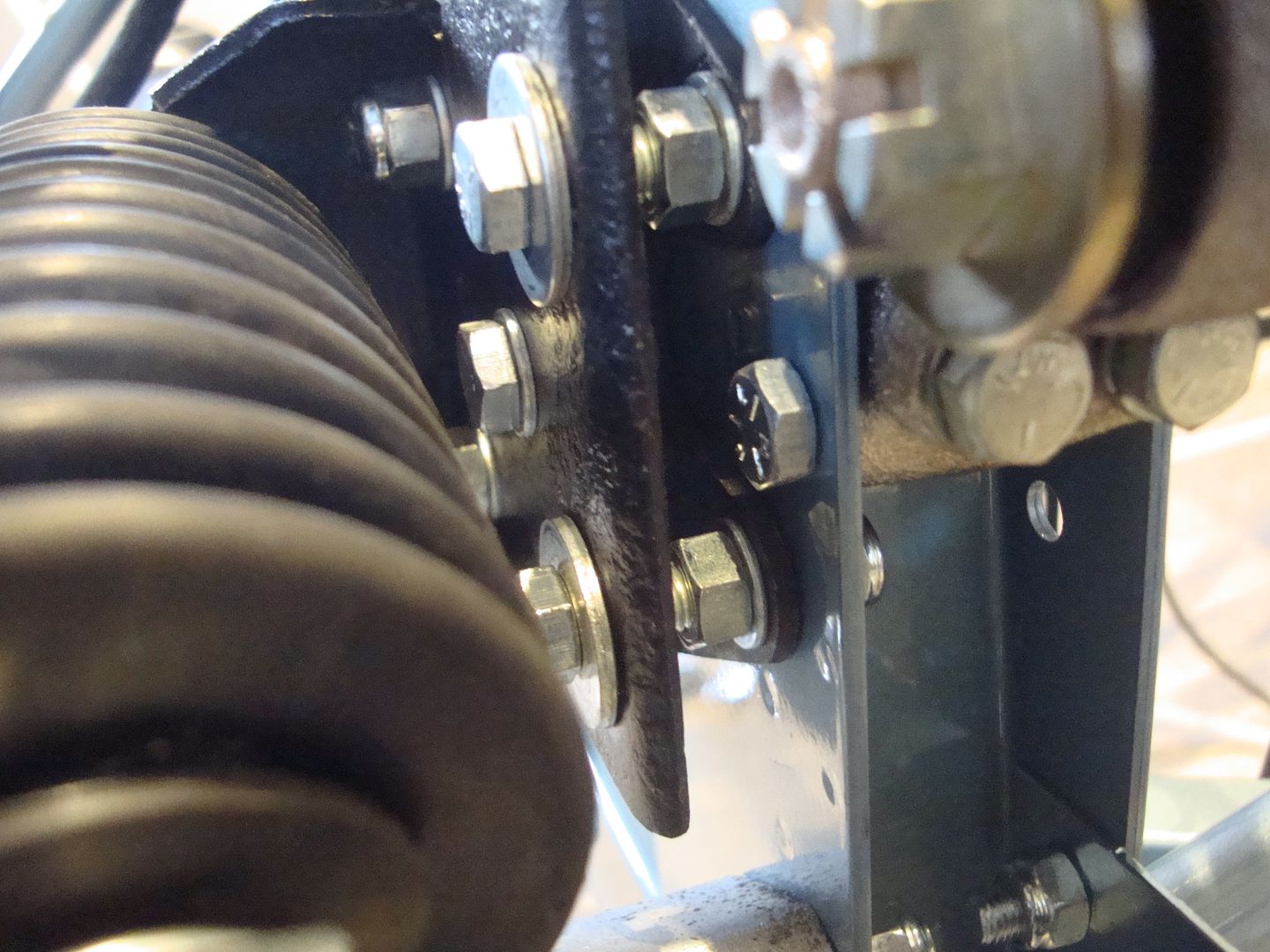

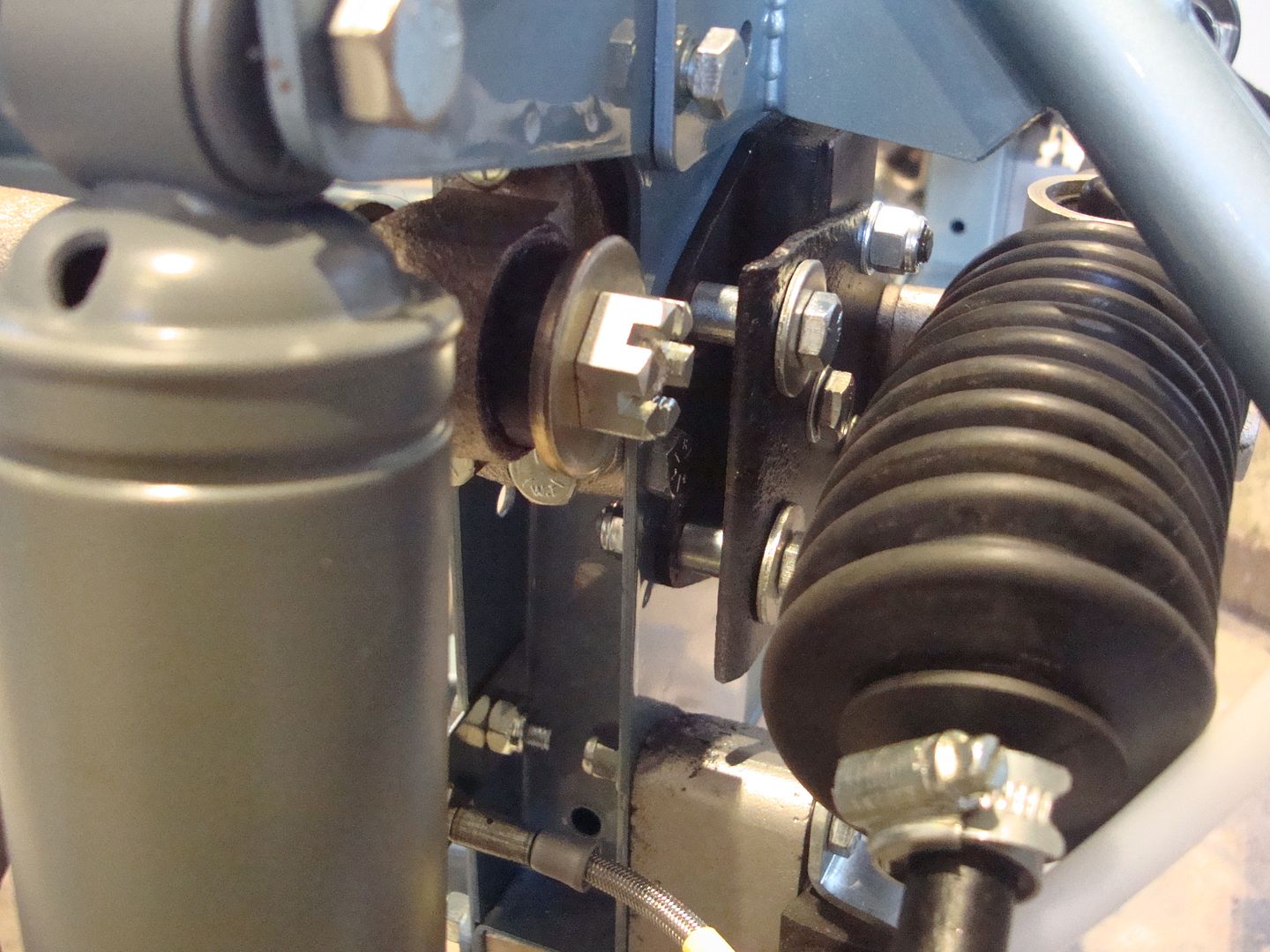

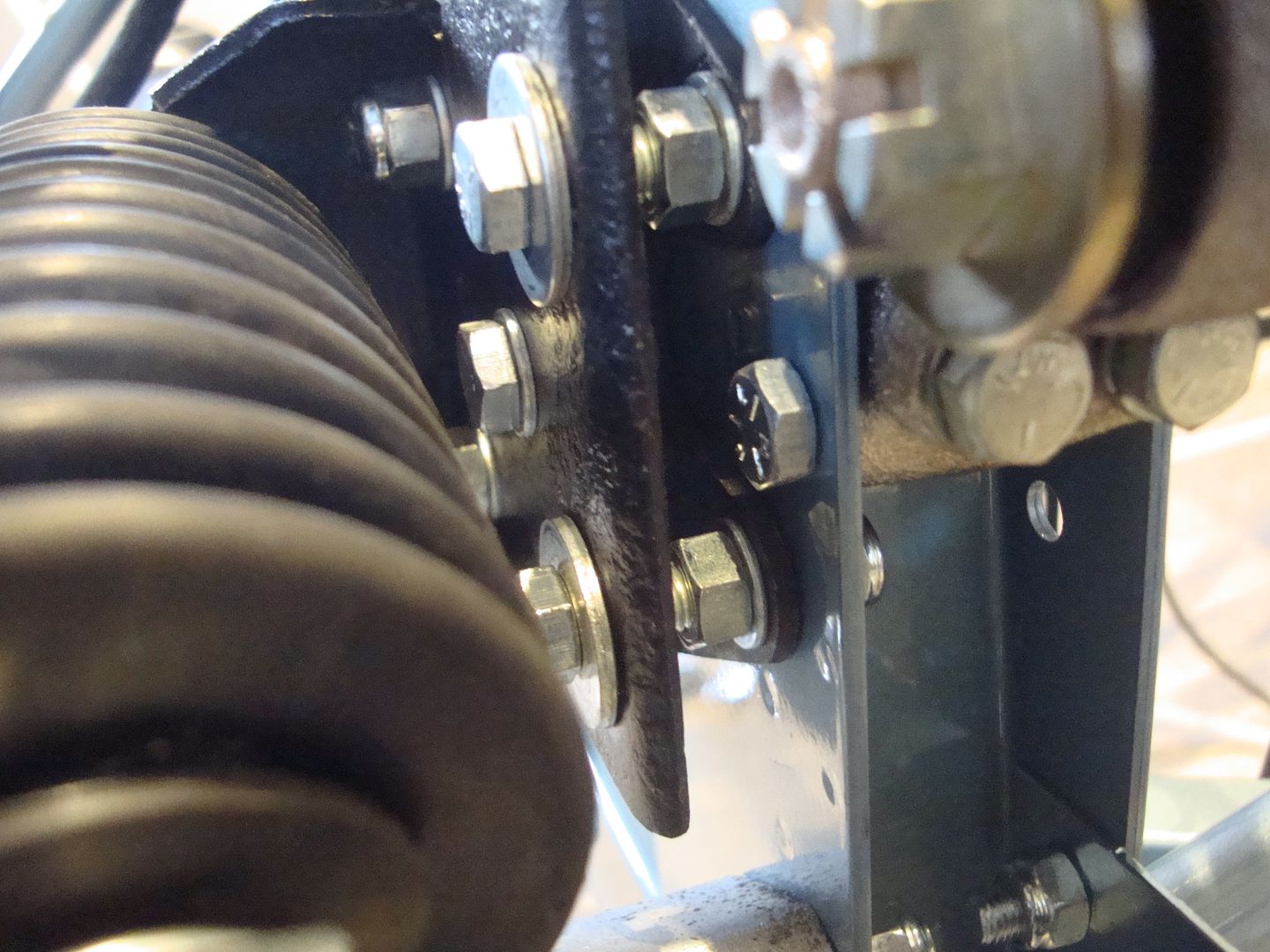

this is how it ended up....lets hope this is correct

Quote message

Hi Andrew, again for what it's worth, it would appear that effectively the spacers on the non column side are replaced by locking nuts that allow you to put a small amount of clamping tension on the rubber mount, limiting its movement under normal driving conditions while still retaining the fail safe feature. So working from the front of the car towards the bulkhead you would have;

set bolt head - washer - steering mount metal plate - washer - locknut -threaded part of set bolt - locknut - steering mount metal plate - picture frame - locknut.

Hope this makes sense!

Simon

However, without the benefit of either a suitable schematic in the manual or the parts book, or having failed to take enough note of the dismantling ( that's where the real problem lies!) it is NOT clear in the manual how the various nuts bolts, washers, spacers fit. Added to that, there is no explanation of why there would be a different set up on each side of the rack, it was a clear case for asking the question. All it needed was a simple explanation which I did eventually get. I still maintain that without the benefit of making a note of how it was pulled down, the books DO NOT detail how it goes back together. Simples! Anwyay, I am sure Peter will not have taken offence...as they say, if you live by the sword, then you die by the sword!

this is how it ended up....lets hope this is correct

Quote message

Hi Andrew, again for what it's worth, it would appear that effectively the spacers on the non column side are replaced by locking nuts that allow you to put a small amount of clamping tension on the rubber mount, limiting its movement under normal driving conditions while still retaining the fail safe feature. So working from the front of the car towards the bulkhead you would have;

set bolt head - washer - steering mount metal plate - washer - locknut -threaded part of set bolt - locknut - steering mount metal plate - picture frame - locknut.

Hope this makes sense!

Simon

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#24

Thanks for the pictures Andrew. From the various manuals etc this is my understanding of how it should be but would love to have confirmation of this.

This is a great help for those like me who never had them on the car in the first place or as you say maybe overlooked this area in their hast to strip down.

Funnily enough it was Peter's own words "steering rack mount with correct spacer and penny washer. Two are used here for extra security." on page 30 of his excellent buyers guide book, that first set me off on my quest for the elusive correct set up.

Simon

This is a great help for those like me who never had them on the car in the first place or as you say maybe overlooked this area in their hast to strip down.

Funnily enough it was Peter's own words "steering rack mount with correct spacer and penny washer. Two are used here for extra security." on page 30 of his excellent buyers guide book, that first set me off on my quest for the elusive correct set up.

Simon

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#25

Andrew

From the Forum Knowledge Base: https://dl.dropboxusercontent.com/u/849 ... rdware.pdf

You will also find the correct sequence is detailed in the SPC - not the pictures, the associated text.

From the Forum Knowledge Base: https://dl.dropboxusercontent.com/u/849 ... rdware.pdf

You will also find the correct sequence is detailed in the SPC - not the pictures, the associated text.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#26

thank you David. I had used this marvellous work before and indeed referred to it for this work too. thanks

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#27 Re: Steering Rack fail safes

Re reading this thread, I am somewhat reluctant to open it up again! But for Peter , it really is the thread that keeps on giving

Anyway, Just doing a bit of tinkering on the 3.8 and I noticed I have developed a squeak when turning the steering. What I have found is that the flat penny washers that on the non pinion side should be free to turn, was a bit too tight and was fouling on the rack bracket. This was certainly the cause of a squeak. Now on the other side, the upper of the two penny washers which sit on the top of the tubular spacer was also touching the rack bracket. What this means is that when the rack moves slightly on its rubber mount, it will squeak against the washers, as per the other side. This situation has come about because the bolts and spacer tubes supplied as part of the fail safe kit were a bit short or perhaps the rack mounting is too thick. If you study the photos earlier in this thread you will see that on my car, the blue car, the washers are touching the rack bracket, on the red car the tubular spacers allow the washer to sit proud of the rack bracket. Has anyone else grappled with this? Easy enough to put right I guess with longer bolts and spacers, but would appreciate any comments.

Finally, I do think my steering is a bit stiff but I am having difficulty in diagnosing whether its the column bushes, rack or uprights. Any way to check the rack? It was the only bit of the car I did not overhaul.

Anyway, Just doing a bit of tinkering on the 3.8 and I noticed I have developed a squeak when turning the steering. What I have found is that the flat penny washers that on the non pinion side should be free to turn, was a bit too tight and was fouling on the rack bracket. This was certainly the cause of a squeak. Now on the other side, the upper of the two penny washers which sit on the top of the tubular spacer was also touching the rack bracket. What this means is that when the rack moves slightly on its rubber mount, it will squeak against the washers, as per the other side. This situation has come about because the bolts and spacer tubes supplied as part of the fail safe kit were a bit short or perhaps the rack mounting is too thick. If you study the photos earlier in this thread you will see that on my car, the blue car, the washers are touching the rack bracket, on the red car the tubular spacers allow the washer to sit proud of the rack bracket. Has anyone else grappled with this? Easy enough to put right I guess with longer bolts and spacers, but would appreciate any comments.

Finally, I do think my steering is a bit stiff but I am having difficulty in diagnosing whether its the column bushes, rack or uprights. Any way to check the rack? It was the only bit of the car I did not overhaul.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Series1 Stu

- Posts: 1650

- Joined: Thu Feb 02, 2017 12:26 pm

- Location: Shropshire

#28 Re: Steering Rack fail safes

Hi Andrew

Start by popping the track rod ends and checking for stiffness in the uprights and also in the rack and column. If you then can't decide whether it's column or rack, disconnect the column from the rack at the universal joint and check again.

Painful process of elimination, I'm afraid.

Regards

Start by popping the track rod ends and checking for stiffness in the uprights and also in the rack and column. If you then can't decide whether it's column or rack, disconnect the column from the rack at the universal joint and check again.

Painful process of elimination, I'm afraid.

Regards

Stuart

If you can't make it work, make it complicated!

'62 FHC - Nearing completion

'69 Daimler 420 Sovereign

'78 Land Rover Series 3 109

If you can't make it work, make it complicated!

'62 FHC - Nearing completion

'69 Daimler 420 Sovereign

'78 Land Rover Series 3 109

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#29 Re: Steering Rack fail safes

yep....what I thought. I suppose I was hoping there was a way to test the rack. I will of course drop the track rod ends off , but its a right old pain to pull the column back! thanks though.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#30 Re: Steering Rack fail safes

Hi Andrew...if you look in the service manual....you will see that during setting up the rack scales are used on the tie rod ends to determine how tight the ball joints should be..... Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

Series1 Stu

- Posts: 1650

- Joined: Thu Feb 02, 2017 12:26 pm

- Location: Shropshire

#31 Re: Steering Rack fail safes

It's probably not what you want to hear but if the rack is the only thing that wasn't refurbished during restoration then that's where my money would be. Although, the reproduction column bushes are of desperately poor quality.

Good luck anyway.

Regards

Good luck anyway.

Regards

Stuart

If you can't make it work, make it complicated!

'62 FHC - Nearing completion

'69 Daimler 420 Sovereign

'78 Land Rover Series 3 109

If you can't make it work, make it complicated!

'62 FHC - Nearing completion

'69 Daimler 420 Sovereign

'78 Land Rover Series 3 109

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#32 Re: Steering Rack fail safes

Yes indeed. I shall pop off the track rod ends and go through the process of elimination. However, the best way to "feel' the stiffness is through the steering wheel which requires the column to be fitted of course. Hence my enquiry as to whether there is a test for the rack. I understand the point Steve you made, but that about the tension in the arms on the ball joint I think. Of course there will be some effect on overall movement, but I am wondering whether the actual rack need pulling apart and overhauling. I shall read the rack overhaul instructions.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#33 Re: Steering Rack fail safes

Yes, we were short on polemics this last few days so here's one floated to the top again.

I've driven for 15 years with a car that had no safety spacers or retaining washers of any sort to cope with failed steering-rack mountings, and I'm ashamed to admit that it was these postings in November last year (by which time the car was off the road) that drew my attention to their very existence.

The steering has always felt perfect to me, and the idea that the missing adjustable constraints on the non-column side of the rack mountings might affect bump-steer escapes me completely.

I'd be the first to credit Jaguar for knowing what they were doing, but cannot grasp why four spacers - two on each side - would not have been adequate to make the car safe and nice to drive.

After all, as my rubbers never failed, that's in fact the condition I've been happily driving it in for the last 15 years.

I'm reluctant to fall into "The Forum Valve Clearance Syndrome" but do wonder if anyone can see something I can't regarding this rack-mounting scenario.

Yes, I have read these exchanges

viewtopic.php?f=4&t=5271

but they don't help.

I don't buy for a second the idea that a fore-and-aft constraint on one end and a side-to-side on the other, when these anchorages are separated by more than 50cm, might constitue a rational way to limit degrees of freedom.

I suspect the key might be Jaguar's insistence that the spacers be located at the same side as the steering wheel ?

The rack and the wheels have no clue where the driver is, so the position of the spacers is irrelevant to the steering of the car BUT as the steering torque comes down the column, maybe it was judged necessary to give the driver's side rubber rack-mount slightly LESS freedom to move around laterally (the spacers obviously being bigger than the bolts inside them) and MORE in a fore-and-aft sense (the washers standing proud of the rack) to cope with any loads coming down from the wheel ?

Hence spacers, and the clearance under their washers, always on the driver's side ?

PS - Is it that obvious it's pissing it down outside ?

I've driven for 15 years with a car that had no safety spacers or retaining washers of any sort to cope with failed steering-rack mountings, and I'm ashamed to admit that it was these postings in November last year (by which time the car was off the road) that drew my attention to their very existence.

The steering has always felt perfect to me, and the idea that the missing adjustable constraints on the non-column side of the rack mountings might affect bump-steer escapes me completely.

I'd be the first to credit Jaguar for knowing what they were doing, but cannot grasp why four spacers - two on each side - would not have been adequate to make the car safe and nice to drive.

After all, as my rubbers never failed, that's in fact the condition I've been happily driving it in for the last 15 years.

I'm reluctant to fall into "The Forum Valve Clearance Syndrome" but do wonder if anyone can see something I can't regarding this rack-mounting scenario.

Yes, I have read these exchanges

viewtopic.php?f=4&t=5271

but they don't help.

I don't buy for a second the idea that a fore-and-aft constraint on one end and a side-to-side on the other, when these anchorages are separated by more than 50cm, might constitue a rational way to limit degrees of freedom.

I suspect the key might be Jaguar's insistence that the spacers be located at the same side as the steering wheel ?

The rack and the wheels have no clue where the driver is, so the position of the spacers is irrelevant to the steering of the car BUT as the steering torque comes down the column, maybe it was judged necessary to give the driver's side rubber rack-mount slightly LESS freedom to move around laterally (the spacers obviously being bigger than the bolts inside them) and MORE in a fore-and-aft sense (the washers standing proud of the rack) to cope with any loads coming down from the wheel ?

Hence spacers, and the clearance under their washers, always on the driver's side ?

PS - Is it that obvious it's pissing it down outside ?

Last edited by rfs1957 on Tue Apr 24, 2018 9:00 pm, edited 1 time in total.

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#34 Re: Steering Rack fail safes

By the time they got to the S3 Jaguar were fitting two security bolts and spacers each side. Perhaps specified that way because of the wider wheels and power steering?

Cheers,

Cheers,

Adrian Turner

S3 OTS & FHC

S1 FHC

XK140 FHC

S3 OTS & FHC

S1 FHC

XK140 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

david muir

- Posts: 244

- Joined: Mon Feb 20, 2012 9:24 pm

- Location: Perthshire

#35 Re: Steering Rack fail safes

Interesting thread and having just checked my , '64 3.8, have found that I have spacers on both sides of car and all clamped tight! Will re-do the nearside to correct specification......wonder if it'll feel any different?-probably not!

1964 3.8 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#36 Re: Steering Rack fail safes

Hi Rory. Good news/bad news. The fact that I agree with every word of the above either makes me as clever as a bona fide race engineer, or you as dumb as me.

Don't say this in polite American company.

I guess that would depend on your reference point:- forces fed in from the road to the rack and its pinion, or vice versa? I was going to make a joke about playing both ends off against the middle, but you get my ‘drift’.

If not a second, can I sell you at least a credulous nanosecond? I suppose I was letting my life sciences mentality show, where one starts by looking at a system to see what it does and works backwards from that. It's what you have to do when studying fiendishly complex living things we did didn't invent, whereas you engineering wallahs get to build from scratch or, if you're Chinese, hack your joint-venture's IP. In the current case the only options are that what we both observe (axial/radial constraints) is what the system was designed to deliver, or a side-effect of some other objective neither of us sees yet. Given that empiricism has served humanity well for over 4 centuries, I think a moment's obeisance to the WYSIWYG deity is an appropriate gesture before we move on, n'est-ce pas?

I’d buy that. Do you take Amex?rfs1957 wrote: ↑Mon Feb 05, 2018 11:32 amI suspect the key might be Jaguar's insistence that the spacers be located at the same side as the steering wheel ? The rack and the wheels have no clue where the driver is, so the position of the spacers is irrelevant to the steering of the car BUT as the steering torque comes down the column, maybe it was judged necessary to give the driver's side rubber rack-mount slightly LESS freedom to move around laterally (the spacers obviously being bigger than the bolts inside them) and MORE in a fore-and-aft sense (the washers standing proud of the rack) to cope with any loads coming down from the wheel ?

Hence spacers, and the clearance under their washers, always on the driver's side ?

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#37 Re: Steering Rack fail safes

Pete, if it's taken a year for my hypothesis to find a buyer, then it's obviously not a very valuable one and there can therefore be no charge !!!

Rory

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

3.8 OTS S1 Opalescent Silver Grey - built May 28th 1962

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#38 Re: Steering Rack fail safes

I was hoping we might flush out an anecdotal data point from David Muir by prompting feedback on his result - though we probably know how it worked out.

As Andrew put it: The thread that keeps on giving... :-)

As Andrew put it: The thread that keeps on giving... :-)

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#39 Re: Steering Rack fail safes

I have some practical input, at least on part of this. The adjustable failsafes with the washers have a definite effect on the feel of the steering. When I replaced my steering rack mounts, it seems I’d overtightened the adjustable failsafes. My definition of just making contact was obviously slightly tighter than Jaguar’s. Anyway, when I drove the car it had a horrid stiction either side, and across the dead ahead position. It would pull slightly to whichever side the rack was sticking to, and wouldn’t self centre properly. When I readjusted the rack mounts to ever so slightly looser, the regular feel and self centring came back.

Incidentally, the steering didn’t feel any different after fitting poly mounts in place of the original metalastic mounts, though that may be because it has power steering.

Incidentally, the steering didn’t feel any different after fitting poly mounts in place of the original metalastic mounts, though that may be because it has power steering.

Tom

1970 S2 FHC

1970 S2 FHC

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#40 Re: Steering Rack fail safes

Just noticed this thread and thought I’d chip in.

I’m “going over”the front end of my S3 inc the steering system, during the C19 event.

My rack is mounted as shown in the pics below, ie. the Safety bolts/bushes are rubber bonded bushes that fit quite firmly in the larger holes of the main mounting plates that attach to the mounts and frame.

They appear not to be some cobbled together bush, but a good fit, and look able to do the job and maintain a degree of movement under severe conditions the steel bush lining the rubber outer is bonded.

I hope that hasn’t confused the discussion.

Peter

I’m “going over”the front end of my S3 inc the steering system, during the C19 event.

My rack is mounted as shown in the pics below, ie. the Safety bolts/bushes are rubber bonded bushes that fit quite firmly in the larger holes of the main mounting plates that attach to the mounts and frame.

They appear not to be some cobbled together bush, but a good fit, and look able to do the job and maintain a degree of movement under severe conditions the steel bush lining the rubber outer is bonded.

I hope that hasn’t confused the discussion.

Peter

Peter {XKE V12HE efi}

XKRS

RR Phantom 3 1937 Sedanca de Ville.

XKRS

RR Phantom 3 1937 Sedanca de Ville.

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |