dash panel

#1 dash panel

A bit of wisdom required please. Battling away restoring my 62 Series One RHD Roadster and at the dashboard and loom stage. The dropdown instrument panel behind the covering piece of aluminium dots is copper plated or in my case rust and copper. Two attempts to replate in copper locally (Norfolk) have proved v unsatisfactory and casting my net further to a couple of the better known electroplaters has resulted in prices of ?140??

My questions...

is copper plating necessary or just "showy" . Are you all copper plating or doing something else?

if you have copper plated where did you go for a good job done at a reasonable price? ( that's always assuming you think ?140 is a lot?)

thanks Graham

My questions...

is copper plating necessary or just "showy" . Are you all copper plating or doing something else?

if you have copper plated where did you go for a good job done at a reasonable price? ( that's always assuming you think ?140 is a lot?)

thanks Graham

E type renovation .... 1962 3.8 Ser1 RHD DHC

If you're going through hell, keep going. ~Winston Churchill

If you're going through hell, keep going. ~Winston Churchill

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#2

Dear Graham,

The order in which plating has to happen is a function of how electropositive each metal is and this dictates what can be plated onto what. For example, with chrome plating, copper is plated first, then nickel, then chrome because chrome will happily stick to nickel anfd nickel will happily stick to copper.

Copper is thus often used as the first strike coat. It has the very useful property of also being very soft, so any imperfections in the surface can be filled in and polished back to give a flat surface and then built up again, polished until a flat surface is obtained. The final top coats of whatever metal is required are vanishingly thin and would show up as an uneven pitted surface if this were not done.

This may explain why the quoted price is what it is - it contains perhaps many iterations of plating and also of polishing because the plater may be looking at achieving an unpitt4ed result.

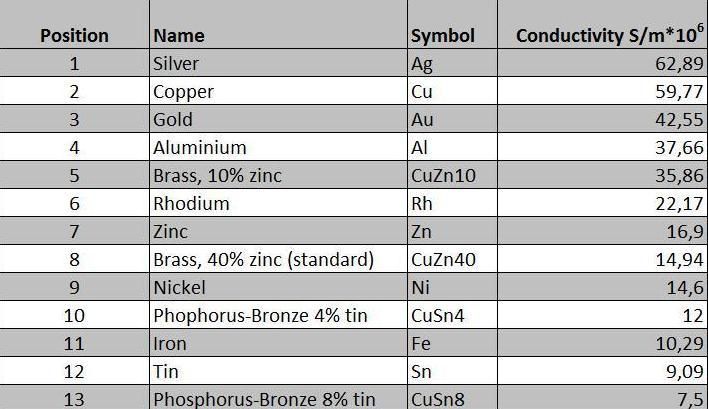

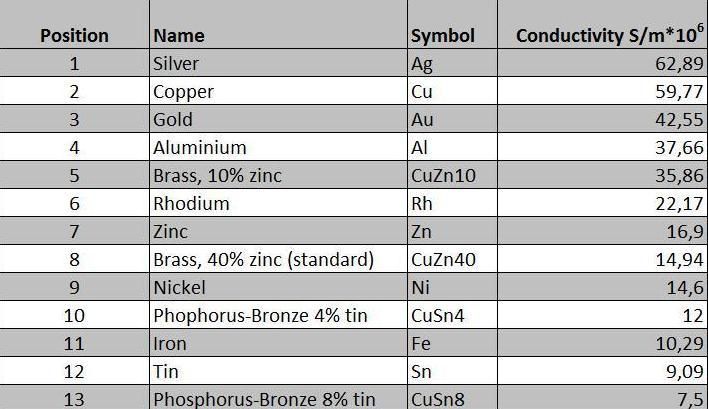

In this case however, if you have dash gauges sitting on this panel, then their ability to complete their electrical circuits may be down to how well they are connected to the panel electrically and copper is an excellent conductor, so the visual appearance may be trivial, but ability to remain properly connected to the chassis may not.

kind regards

Marek

The order in which plating has to happen is a function of how electropositive each metal is and this dictates what can be plated onto what. For example, with chrome plating, copper is plated first, then nickel, then chrome because chrome will happily stick to nickel anfd nickel will happily stick to copper.

Copper is thus often used as the first strike coat. It has the very useful property of also being very soft, so any imperfections in the surface can be filled in and polished back to give a flat surface and then built up again, polished until a flat surface is obtained. The final top coats of whatever metal is required are vanishingly thin and would show up as an uneven pitted surface if this were not done.

This may explain why the quoted price is what it is - it contains perhaps many iterations of plating and also of polishing because the plater may be looking at achieving an unpitt4ed result.

In this case however, if you have dash gauges sitting on this panel, then their ability to complete their electrical circuits may be down to how well they are connected to the panel electrically and copper is an excellent conductor, so the visual appearance may be trivial, but ability to remain properly connected to the chassis may not.

kind regards

Marek

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#3

I have never been able to fully understand the reason Jaguar copper plated the rear of the dash panel. Although copper would indeed provide a good earth return the instruments are held in place by metal brackets which are pressed firmly against the dash, each instrument has an earth terminal and there are earth posts riveted to it. Bare steel would have been out of the question but I can't see why they did not use cadmium plate which is almost as good a conductor as copper. Copper is also subject to oxidation to form copper carbonate aka verdigris which itself contains various poisonous compounds. My guess is the copper was applied for decorative purposes for a bit of 'wow' factor when the owner lowered the centre dash.

Zinc plating would be acceptable electrically.

Zinc plating would be acceptable electrically.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#4 Re: dash panel

Graham -

I would expect you could find a replacement panel that does not need replating for a lot less than that.

Even those fitted to other Jaguars of the same era should be a direct swap.

Joe

I would expect you could find a replacement panel that does not need replating for a lot less than that.

Even those fitted to other Jaguars of the same era should be a direct swap.

Joe

1963 3.8 OTS

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#5

Not quite - the hinges are different on the saloons and would require welding work.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#6

Is it obvious that a panel is from a saloon or are the pivots just in a slightly different location?Heuer wrote:Not quite - the hinges are different on the saloons and would require welding work.

Joe

1963 3.8 OTS

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#7

E-Type:

Last edited by Heuer on Fri Jul 17, 2015 12:55 pm, edited 1 time in total.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#8

Very obvious then !

So to use that it would need the hinges removing and the welding you referred to is for the pivot captive nuts on the sides?

Joe

So to use that it would need the hinges removing and the welding you referred to is for the pivot captive nuts on the sides?

Joe

1963 3.8 OTS

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#9

Correct. Cut off the hinges and then drill and weld the E-Type pivots to the ends. Problem is you will destroy the original embossed black vinyl. Not a problem for 3.8 ally dash or if you are recovering a 4.2 dash. Probably more cost effective to buy new. Robey's have them for about ?95.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#10

Yes, I agree. Or find an E Type one of course.Heuer wrote: Probably more cost effective to buy new.

Joe

1963 3.8 OTS

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#11

Just use the old one; it will almost certainly be fine.

Andrew.

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#12

But gold would be almost as good and increase the WOW factor.Heuer wrote:

Zinc plating would be acceptable electrically.

Andrew.

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

881824, 1E21538. 889457. 1961 4.3l Mk2. 1975 XJS. 1962 MGB

http://www.projectetype.com/index.php/the-blog.html

Adelaide, Australia

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#13

thanks everyone for your comments. Hadn't thought buying new was an option as interestingly the web sites for the big specialists all default the original Jag part number for the panel as not found so if David is correct and Robey has them it just proves picking up the phone is always worth a try. You can't beat the old ways!!

If you are having a similar dilemma on what to do, just remember David's comments above ... we men do like the "wow" factor when we lower our centre dash !! :D :D :D

If you are having a similar dilemma on what to do, just remember David's comments above ... we men do like the "wow" factor when we lower our centre dash !! :D :D :D

E type renovation .... 1962 3.8 Ser1 RHD DHC

If you're going through hell, keep going. ~Winston Churchill

If you're going through hell, keep going. ~Winston Churchill

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#14

Addendum... none of the big boys including Robey make them!! There is an opportunity for someone!!

E type renovation .... 1962 3.8 Ser1 RHD DHC

If you're going through hell, keep going. ~Winston Churchill

If you're going through hell, keep going. ~Winston Churchill

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#15

I assume you have tried Hutsons and Richard Smith? Might be worth contacting:

Ken Verity

Ken Jenkins

M&C Wilkinson

Monocoque Metalworks

RS Panels make one in aluminium but it is configured for the LWE so it is missing a few holes.

On the other hand converting a Saloon version would not be difficult. Cut off hinges, drill two holes, weld two nuts on inside. This one would do it: http://tinyurl.com/nh6ygp9 or this one with a BIN price of ?395: http://tinyurl.com/qzscg8l

Ken Verity

Ken Jenkins

M&C Wilkinson

Monocoque Metalworks

RS Panels make one in aluminium but it is configured for the LWE so it is missing a few holes.

On the other hand converting a Saloon version would not be difficult. Cut off hinges, drill two holes, weld two nuts on inside. This one would do it: http://tinyurl.com/nh6ygp9 or this one with a BIN price of ?395: http://tinyurl.com/qzscg8l

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |