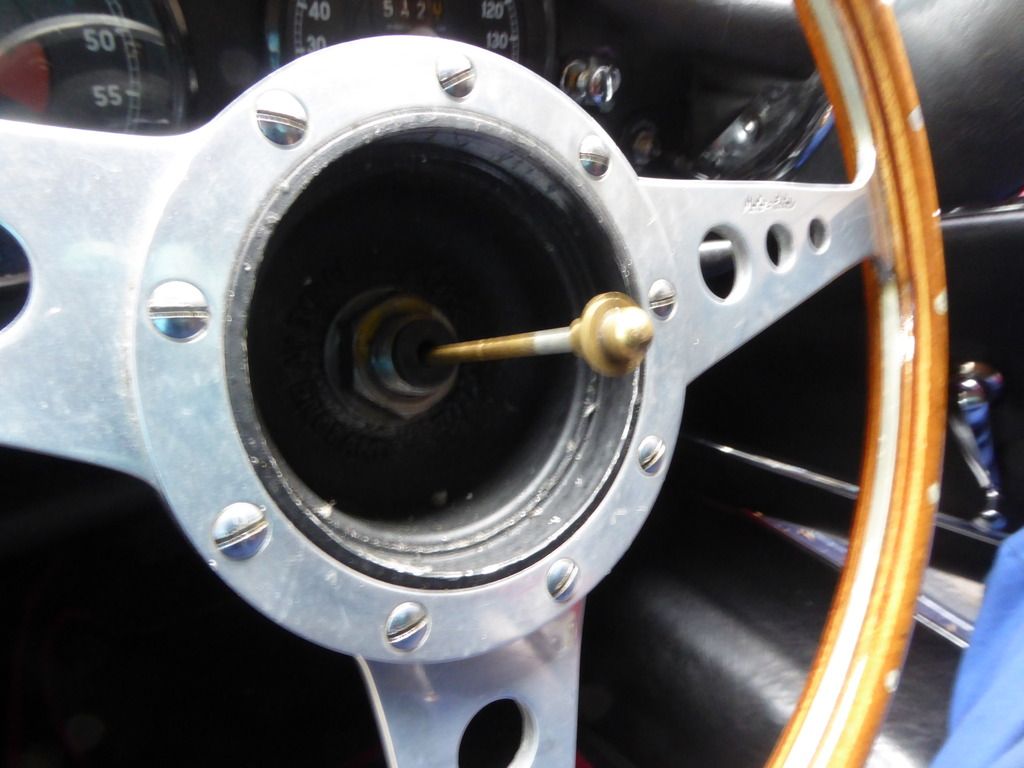

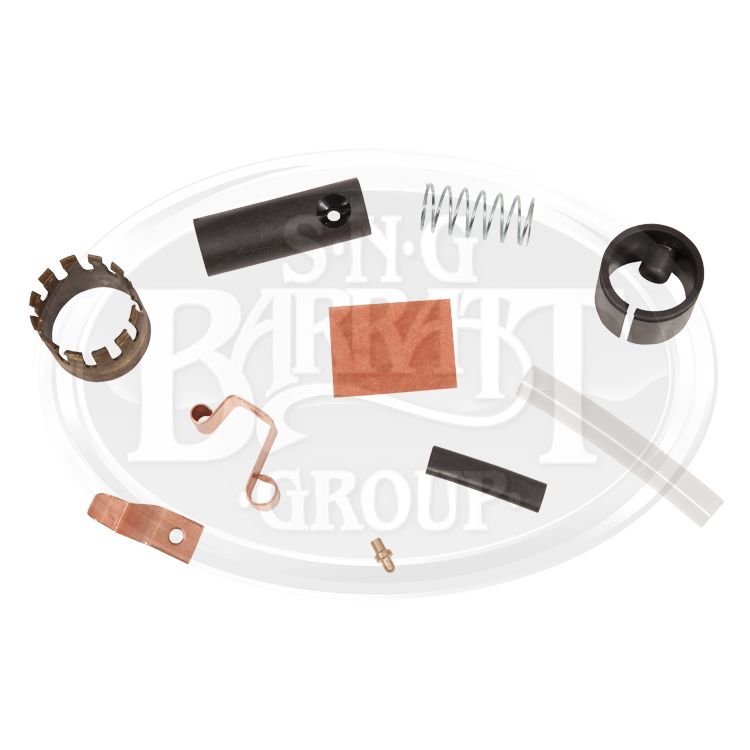

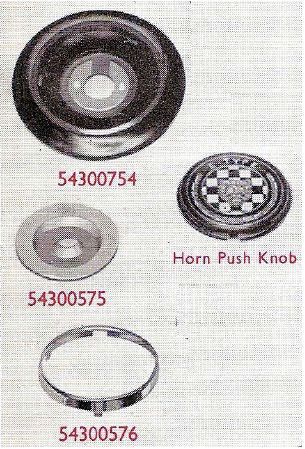

adam wrote:The retaining ring takes the brass contact, and the cut out locates the horn push to stop horn push spinning round. Also without retaining ring it would just fall out. The ring is the stop to locate it on the centre, because without it the hub cap badge is the same diameter as the hole.

Adam

All true Adam, but the hub cap is not designed and does not function as a horn push, or

vice versa so nothing is 'missing' in either incarnation

It's just that the decorative emblem part, and that part alone, can be switched from the former to the latter with a bit of work. Most will be happy with the ready-made repro part, but for those who want an original golden Jag emblem and don't mind a bit of fettling, S3 hub caps are a source of the real McCoy.