low speedo reading

-

mgcjag

Topic author - Moderator

- Posts: 8097

- Joined: Fri Jul 09, 2010 6:15 pm

- Location: Ludlow Shropshire

#1 low speedo reading

Hi All...please ignore this as a new post....it dates from 2011....I moved a post incorrectly so it now appears as new.....Steve

Hi All.....& have a great new year.......A friends recently purchase a US converted S2 roadster.....Speedo was reading very very low no more than about 20mph....replaced with my speedo from a S2 2+2 but still the same...also swapped over the gearbox end angle drive & cable.........Questions..is there a drive gearing in the gearbox? I do realise that speedos have different callibrations but didnt think it would have such a wide variation......any ideas......PS where is the gearbox number located....Thanks...Steve

Hi All.....& have a great new year.......A friends recently purchase a US converted S2 roadster.....Speedo was reading very very low no more than about 20mph....replaced with my speedo from a S2 2+2 but still the same...also swapped over the gearbox end angle drive & cable.........Questions..is there a drive gearing in the gearbox? I do realise that speedos have different callibrations but didnt think it would have such a wide variation......any ideas......PS where is the gearbox number located....Thanks...Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

#2

There is a helical drive gear on the gearbox mainshaft which meshes with the speedo drive gear which protrudes from the right hand side of the gearbox rear cover . There are two possibilities from the sound of things :

i.the plastic helical drive gear ( P/N C 21310 ) has stripped - I would regard this as a bit unlikely

ii.much more likely is that the square ended drive shaft of C 21310 has ceased to be square in shape, or has split, so that it no longer positively drives the input end of the angle drive unit

The gearbox number should be on the left hand top cover edge about in line with the gear lever

i.the plastic helical drive gear ( P/N C 21310 ) has stripped - I would regard this as a bit unlikely

ii.much more likely is that the square ended drive shaft of C 21310 has ceased to be square in shape, or has split, so that it no longer positively drives the input end of the angle drive unit

The gearbox number should be on the left hand top cover edge about in line with the gear lever

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

mgcjag

Topic author - Moderator

- Posts: 8097

- Joined: Fri Jul 09, 2010 6:15 pm

- Location: Ludlow Shropshire

#3

Hi Guys........pulled out the drive from the gearbox all looks ok...rigged a drill to the nylon drive & the speedo moved way up to 40mph ( as fast as my drill would go........So where is the problem is it just a callibration mis match?....speedo No is Sn-6332/01A1312 & gearbox no is KE12486....Thanks Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#4

Speedo data here: http://etypeuk.com/forum/viewtopic.php?t=951 Although the 6332/01A is not listed (00A and 02A are) I suggest it is for a mph 3.31 diff.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

mgcjag

Topic author - Moderator

- Posts: 8097

- Joined: Fri Jul 09, 2010 6:15 pm

- Location: Ludlow Shropshire

#5

Hi David would you expect there to be such a difference in the speedo reading. As i said earlier have tried a working speedo from my car with a 3.07 diff & cant get a reading of over 40mph.....could there be any thing wrong in the gearbox?. Only other option is take the cover of the diff to see what ratio it is......Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#6

Steve

There should be a tag on the diff showing the ratio e.g. 43/13. Have you put a drill on the speedo drive gearbox spindle whilst it is still connected to the speedo via the drive cable? If the speedo refuses to go above 40mph whilst in the car, and it works OK via the drill, then I would suspect the helical drive gear - as speed increases it could be slipping on its shaft.

There should be a tag on the diff showing the ratio e.g. 43/13. Have you put a drill on the speedo drive gearbox spindle whilst it is still connected to the speedo via the drive cable? If the speedo refuses to go above 40mph whilst in the car, and it works OK via the drill, then I would suspect the helical drive gear - as speed increases it could be slipping on its shaft.

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

mgcjag

Topic author - Moderator

- Posts: 8097

- Joined: Fri Jul 09, 2010 6:15 pm

- Location: Ludlow Shropshire

#7

Hi David......Just tracked the problem down to the speedo drive gear slipping on the gearbox main shaft........looking through the speedo drive hole in the gearbox we can see the drive cog revolving when we spin a rear wheel......lightly touching the cog stops it & it slips.......Question..can the rear section of the gearbox be removed is situe & what holds the cog in position on the shaft.....many thanks Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

#8

Steve : first of all, do you know what the speed of your drill is . If so, it should not be too difficult to calibrate your speedo, because it appears to be a 1312 turns per mile instrument. Thus a drill speed on the speedocable, not the angle drive , , of 1312 rpm should show 60 mph on the speedo . If the drill speed were 1800 rpm, then it should show 1800/1312 X 60 = 82 mph etc . If 1000 rpm , 46 mph etc . If it is anywhere in that league, then your speedo itself would be ok . Now connect the angle drive and re-measure : some of these are geared down, and some are not. I'm afraid I cannot tell you what yours should be, but if it drives consistently, without slipping, then you have effectively eliminated these as the sources of error. Unfortunately, a not uncommon fault of these speedos, particularly if they have been exposed off the car to a strong magnetic field e.g. Cathode Ray tube electron gun, or microwave , is for the aluminium cup to become de-magnetised and this produces the effects you describe . You can try re-magnetising them using rare-earth ( neodymium) magnets out of e.g an old computer hard disk, but having done it myself I can tell you that it is a hit and miss affair.The other thing to check is that the speedo shaft is running freely. This requires some dismantling and there are a number of good articles about this on the internet ( try googling TR6 speedo for example)

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#9

Stevemgcjag wrote:Hi David......Just tracked the problem down to the speedo drive gear slipping on the gearbox main shaft........looking through the speedo drive hole in the gearbox we can see the drive cog revolving when we spin a rear wheel......lightly touching the cog stops it & it slips.......Question..can the rear section of the gearbox be removed is situe & what holds the cog in position on the shaft.....many thanks Steve

Not as far as I know - gearbox out I think

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

#10

Steve ; oh crikey - disregard my previous post , which I shall leave up in case it helps anyone else. I do not know whther you can get the rear case of the box off with the gearbox in situ . I think it might be possible with a 2+2, but would be a hell of a job in a short chassis car , and it would be absolutely vital to secure the gearbox against anything more than a most minimal drop because if you do not do this, you are likely to damage the bulkhead and cam covers/oil feed / tacho drive. Equally, I do not know what drives the speedo gear - the parts list does not mention a pin of any type and thus the gear ( and the mainshaft) may have an internal flat on it to provide drive . You could try ringing Colin Ford who is the JEC's E type guru and seeing if he knows of a short cut on this one, but candidly I am not optimistic

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

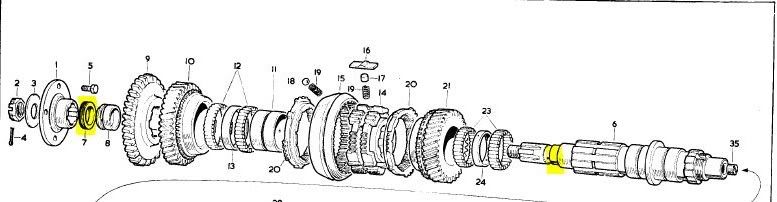

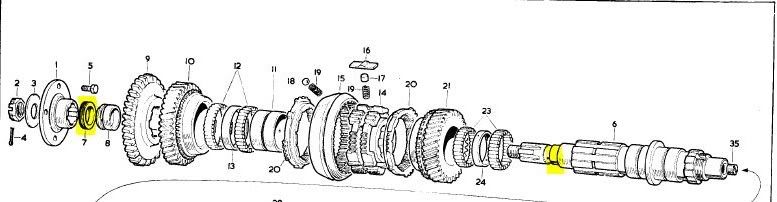

#11

Looking at the parts manual I think there is a slot in the mainshaft to lock the speedometer gear.

1 = u/j flange

7 = speedometer driving gear

8 = distance plate, behind speedometer driving gear

9 = reverse gear

10 = 1st speed gear

1 = u/j flange

7 = speedometer driving gear

8 = distance plate, behind speedometer driving gear

9 = reverse gear

10 = 1st speed gear

David Jones

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

S1 OTS OSB; S1 FHC ODB

1997 Porsche 911 Guards Red

Add your E-Type to our World Map: http://forum.etypeuk.com/viewtopic.php?f=1&t=1810

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

#12

David : you might be correct, although if you look at drawing 14 as well as 15, the milled slot appears as though it takes the Woodruff key which drives the oil pump . The key is item 14-16 P/N C21309 .There is a suggestion, immediately to the rear of the slot on the diagram you have produced, of a hole for a pin, but I cannot trace any pin in the parts list

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

mgcjag

Topic author - Moderator

- Posts: 8097

- Joined: Fri Jul 09, 2010 6:15 pm

- Location: Ludlow Shropshire

#13 Re: low speedo reading

Hi All...please ignore this as a new post.....i was moveing a post and lost it so have just reposted it

So the info below is from 2011....thanks....Steve

Hi Guys.....Disconnected the prop from the gearbox but it would not slide back far enough to remove the rear cover......So disconnected at diff end but still could not move the prop enough. So removed the IRS (needed to come out at some time for some work anyway)...removed exhaust & gearbox support & then had access. removed end flange & end cover plate & all seamed a bit loose in there. refering to the diagram above the drive cog 7 sits between the flange 1 & small oil pump rotor 8. the rotor has a pin attached to slot into rear extension cover & forms a pump for oil to the rear extension. The speedo drive cog has nothing to hold it fixed to the main shaft & just sits between the flange & rotor, the face of the flange it mates to has small cuts all aroung the mating face so i assume this somehow grips the cog.....in hind sight the nut holding the flange was quite loose so was not compressing the flange/cog/rotor enough......waiting new gaskets...will keep you posted......all now reassembled and speedo now working........Steve

So the info below is from 2011....thanks....Steve

Hi Guys.....Disconnected the prop from the gearbox but it would not slide back far enough to remove the rear cover......So disconnected at diff end but still could not move the prop enough. So removed the IRS (needed to come out at some time for some work anyway)...removed exhaust & gearbox support & then had access. removed end flange & end cover plate & all seamed a bit loose in there. refering to the diagram above the drive cog 7 sits between the flange 1 & small oil pump rotor 8. the rotor has a pin attached to slot into rear extension cover & forms a pump for oil to the rear extension. The speedo drive cog has nothing to hold it fixed to the main shaft & just sits between the flange & rotor, the face of the flange it mates to has small cuts all aroung the mating face so i assume this somehow grips the cog.....in hind sight the nut holding the flange was quite loose so was not compressing the flange/cog/rotor enough......waiting new gaskets...will keep you posted......all now reassembled and speedo now working........Steve

Steve

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

69 S2 2+2 (just sold) ..Realm C type replica, 1960 xk150fhc

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |