Clutch disk thickness

#1 Clutch disk thickness

Hi all,

I'm looking for the lower thickness of the clutch disk.

In the V12 manual there is no indication of this.

Mine is 8.5mm. The pressure plate is in good condition without wear but I don't know how to judge the disk.

Thank you for you r help.

cheers

I'm looking for the lower thickness of the clutch disk.

In the V12 manual there is no indication of this.

Mine is 8.5mm. The pressure plate is in good condition without wear but I don't know how to judge the disk.

Thank you for you r help.

cheers

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

christopher storey

- Posts: 5698

- Joined: Sun Mar 09, 2008 3:07 pm

- Location: cheshire , england

#2

You need to examine the disk to see how near to the friction surface the rivets or bonded metal is . There should be at least 3mm of friction material above the metal of the rivets or bonded surface. However, if you have the clutch out of the car, it is false economy not to replace the friction disk ( it is called the driven plate ) as a matter of course

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#3

Is there still 'meat' above the rivet heads? At 8.5 there must be. It's not brand new but it's not on its last legs either. Check all rivets in case there's one that's a bit less compressed than the others. I'd say 1/4 worn, good for another 60-80,000 depending on flat v hilly terrain and driving style.

Most would throw it away but they usually aren't being entirely rational and clutch failure is not sudden. Plus on a V12 it can be replaced with engine in situ although I probably would take the chance to do other jobs if I ever had to. I certainly wouldn't follow the herd. Mangez bien, riez souvent, pensez deux fois pour mieux vivre demain.

Your bell is a Dellow from New Zealand I think.

Pete

Most would throw it away but they usually aren't being entirely rational and clutch failure is not sudden. Plus on a V12 it can be replaced with engine in situ although I probably would take the chance to do other jobs if I ever had to. I certainly wouldn't follow the herd. Mangez bien, riez souvent, pensez deux fois pour mieux vivre demain.

Your bell is a Dellow from New Zealand I think.

Pete

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#4

Thank you bothof you!

Pete, I ve finally found a SKF reference on the bearing. I m now able to go further on the clutch.

Cheers

Pete, I ve finally found a SKF reference on the bearing. I m now able to go further on the clutch.

Cheers

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#5

Chris is right in principle but I'd argue the numbers, based on four plates I just measured:

Where you WILL find at least 3 mm is in the open holes which go right through the material to give acess for the tail of the rivet on the opposite disc to be compressed. If you manage to put the point of your depth gauge against the steel base in the narrow gap between the rivet and the friction material surrounding it. If you do that you will measure the full thickness of the material remaining.

Since the steel in the sandwich varies in thickness, the overall plate thickness is a somewhat arbitrary measure. The safest and most relevant is the amount remaining proud of the highest rivet head on each sides. As long as the rivets aren't flush the plate has some life left but I agree it's not sensible to reuse something borderline. 8.5 mm doesn't sound borderline (my brand new XJ clutch is only 8.1 mm) but without the thickness above the rivet head (not tail) we cannot say. 1.5 mm would be OK for a hobby car driven under 10,000 miles a year IMO.

What gearbox are you putting on the bell Michel? The release bearibg was never going to be an issue if you measure the old one or find a number. The ball race type are pretty generic..

Driven plates are two sided and the friction material is typically around 4mm thick. Each disc has through holes and shouldered holes. The shouldered holes leave at least a millimetre for the rivet head to clamp an the rivet head is about a millimetre thick, so even brand new there would not be 3 mm of material above it, let alone 'at least' that amount. I just measured 1.7 mm on a new V12 plate and that is generous because the face is still rough and unburnished.christopher storey wrote:You need to examine the disk to see how near to the friction surface the rivets or bonded metal is . There should be at least 3mm of friction material above the metal of the rivets or bonded surface. However, if you have the clutch out of the car, it is false economy not to replace the friction disk ( it is called the driven plate ) as a matter of course

Where you WILL find at least 3 mm is in the open holes which go right through the material to give acess for the tail of the rivet on the opposite disc to be compressed. If you manage to put the point of your depth gauge against the steel base in the narrow gap between the rivet and the friction material surrounding it. If you do that you will measure the full thickness of the material remaining.

Since the steel in the sandwich varies in thickness, the overall plate thickness is a somewhat arbitrary measure. The safest and most relevant is the amount remaining proud of the highest rivet head on each sides. As long as the rivets aren't flush the plate has some life left but I agree it's not sensible to reuse something borderline. 8.5 mm doesn't sound borderline (my brand new XJ clutch is only 8.1 mm) but without the thickness above the rivet head (not tail) we cannot say. 1.5 mm would be OK for a hobby car driven under 10,000 miles a year IMO.

What gearbox are you putting on the bell Michel? The release bearibg was never going to be an issue if you measure the old one or find a number. The ball race type are pretty generic..

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#6

Pete,

I?ve look to the thickness above the head of each rivet and it is over 1.5mm. When I will ride the car I will not do so many km per year so I will use it.

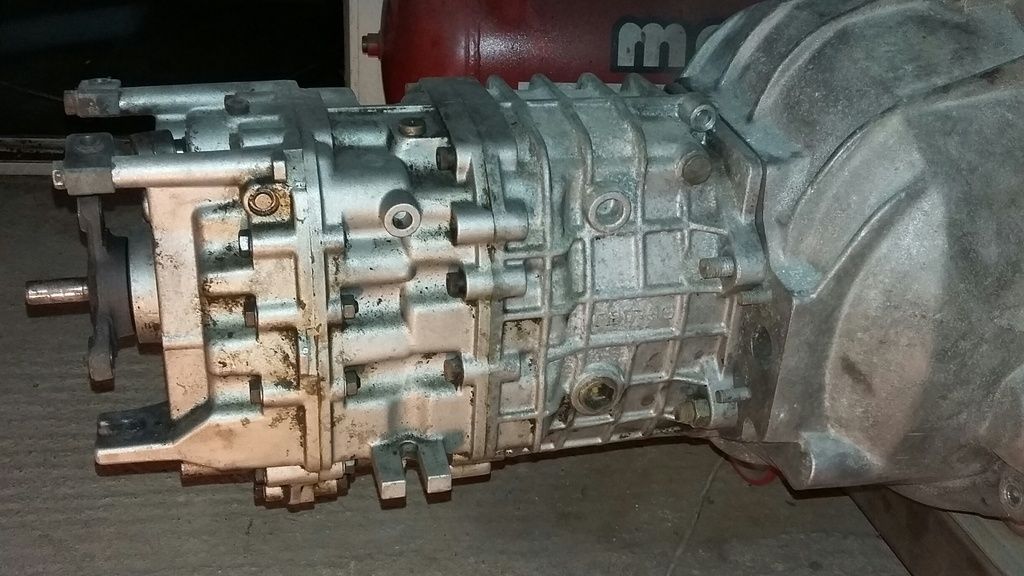

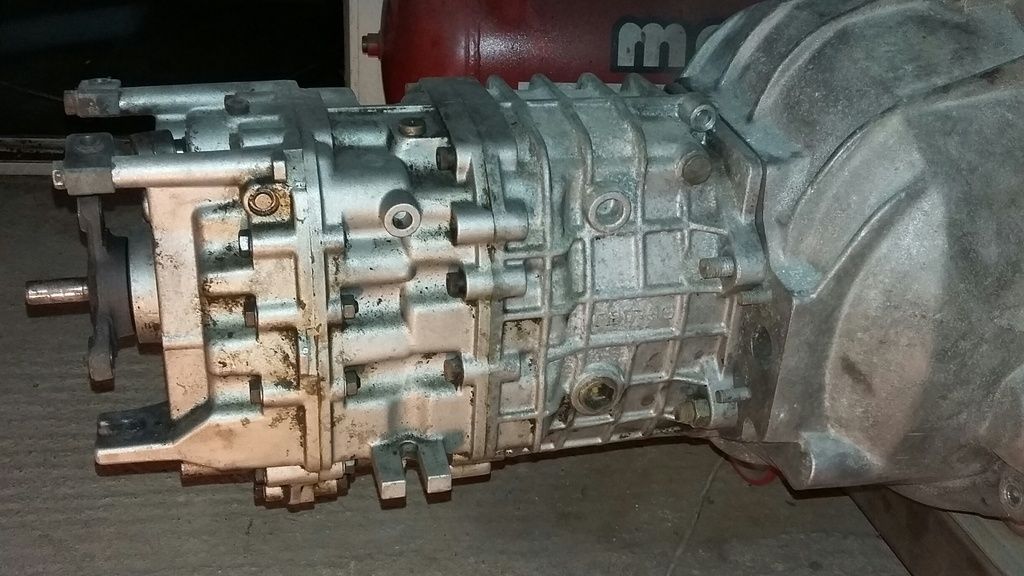

The box I?ve bought is a Getrag 265 with the short tail coming out from a BMW635. It is the same use than the one coming from an XJ but shorter.

It has the speedo drive. It sounds in good condition. I?ve change the 2 oil seals. I now have to place the engine with the gearbox into the car and measure the length the driveshaft will have to have.

Cheers

I?ve look to the thickness above the head of each rivet and it is over 1.5mm. When I will ride the car I will not do so many km per year so I will use it.

The box I?ve bought is a Getrag 265 with the short tail coming out from a BMW635. It is the same use than the one coming from an XJ but shorter.

It has the speedo drive. It sounds in good condition. I?ve change the 2 oil seals. I now have to place the engine with the gearbox into the car and measure the length the driveshaft will have to have.

Cheers

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#7

Nice one. I assume it has Getrag splines on the driven plate to match the input shaft but fits a Jaguar V12 pressure plate? When assembling engine/bell/gearbox from three different makers you need to check the crank pilot bush the same size as the Getrag shaft nose and that the shoulder of the input shaft does not press on the crank (or you will damage the thrust washers),

Pete

Pete

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#8

Pete,

I?ve follow your different items and:

- the spines from the driven plate match with the input shaft from the gearbox.

- the pressure plate fit with the gearbox too. It can be manually placed into the bell housing when fixed on the gearbox. It goes around the tube which is over the input shaft from the Getrag.

- there is not any bush into the crank as the engine was used with an automatic gearbox. Do I?ve to order one for a V12 XJ/S? The diameter from the box shaft nose is 12mm. Do you have any data on this bush. Is it a bearing?

Michel

I?ve follow your different items and:

- the spines from the driven plate match with the input shaft from the gearbox.

- the pressure plate fit with the gearbox too. It can be manually placed into the bell housing when fixed on the gearbox. It goes around the tube which is over the input shaft from the Getrag.

- there is not any bush into the crank as the engine was used with an automatic gearbox. Do I?ve to order one for a V12 XJ/S? The diameter from the box shaft nose is 12mm. Do you have any data on this bush. Is it a bearing?

Michel

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#9

I've just found the STD crank bush reference which is C2226 for the standard gearbox 4.

However, I don't know the sizes.

If you do have them or know how to solve this topic it will be great.

Cheers

However, I don't know the sizes.

If you do have them or know how to solve this topic it will be great.

Cheers

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#10

The Jag uses ten splines and the Getrag something like 20 from memory, but as long as the plate matches you'll be fine. Be sure to fit it the right way round so the centre boss doesn't foul.

A quick measure of four Jag gearboxes shows an average of about 12.6 mm plus the T5 with Jag-pattern input shaft at >12.7 mm. There is some variability due to surface corrosion on a couple of the older boxes. The Getrag is a bit too small for a standard bush so you should really get a special made up if you want to do the job right. This assumes your non-standard bell lines the gearbox up accurately using your dowels. Sintered bronze is best but brass might last a while if you don't sit in gear in traffic all the time. There are very thin sleeves you can use on shafts to repair oil seal wear grooves but I don't know if they are made in 12 mm sizes or if they would suit a moderately loaded fitment.

If your engine is E-type the crank should be drilled for the bush. If it's a later XJ-S or XJ-2 saloon engine it *might* not be drilled.

A quick measure of four Jag gearboxes shows an average of about 12.6 mm plus the T5 with Jag-pattern input shaft at >12.7 mm. There is some variability due to surface corrosion on a couple of the older boxes. The Getrag is a bit too small for a standard bush so you should really get a special made up if you want to do the job right. This assumes your non-standard bell lines the gearbox up accurately using your dowels. Sintered bronze is best but brass might last a while if you don't sit in gear in traffic all the time. There are very thin sleeves you can use on shafts to repair oil seal wear grooves but I don't know if they are made in 12 mm sizes or if they would suit a moderately loaded fitment.

If your engine is E-type the crank should be drilled for the bush. If it's a later XJ-S or XJ-2 saloon engine it *might* not be drilled.

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#11

Hi all, happy new year!

I've goe further on my problem.

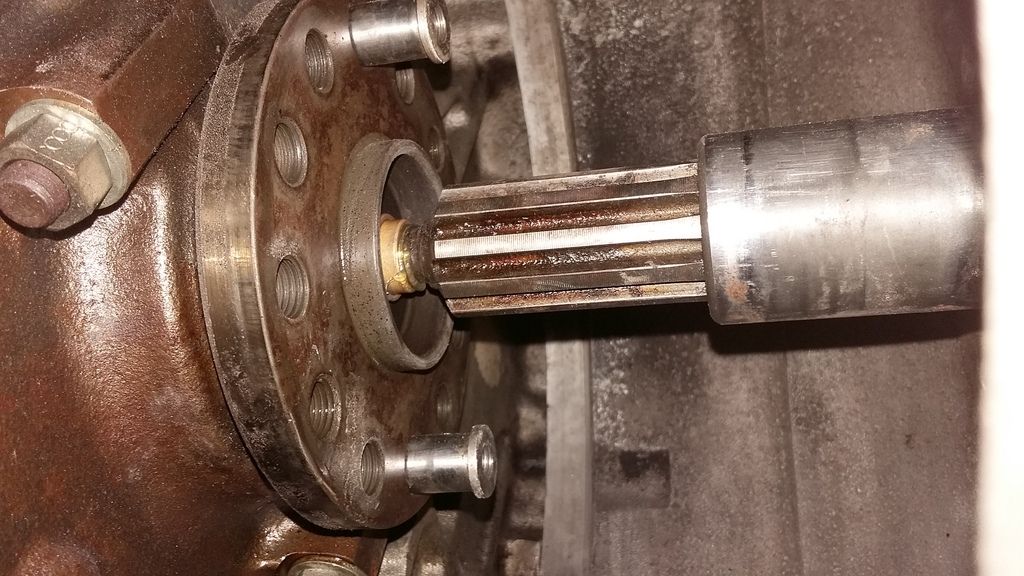

I' ve fixed the bellhousing and the gearbox :

as there is a small access under the belhoussing, I've take a picture. It shows how the nose of the input shaft is close to the crank:

There is ~17mm which are virtualy into the bush. I think it is enough to guide the imput shaft. I now just have to get the bush.

The diameter in the crank is 19mm and the imput shaft is 12.

I 've found a supplier in France and with 2 bushes ( 19mm out 15mm in, and 15mm out 12mm in )I should get the good part. I'll get them on tomorrow.

Cheers.

I've goe further on my problem.

I' ve fixed the bellhousing and the gearbox :

as there is a small access under the belhoussing, I've take a picture. It shows how the nose of the input shaft is close to the crank:

There is ~17mm which are virtualy into the bush. I think it is enough to guide the imput shaft. I now just have to get the bush.

The diameter in the crank is 19mm and the imput shaft is 12.

I 've found a supplier in France and with 2 bushes ( 19mm out 15mm in, and 15mm out 12mm in )I should get the good part. I'll get them on tomorrow.

Cheers.

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

-

PeterCrespin

- Posts: 4561

- Joined: Fri Mar 05, 2010 8:22 pm

- Location: Gaithersburg, Maryland.

- Contact:

#12

Is that the input shaft used in the BMW 6 series? It looks just like the Jag 10-spline. My Getrags had a much finer spline. Your bush plan sounds fineand you are doing the exact right thing by checking everything as you go, due to special parts. Make sure to check the starter while everything is out of the car.

Don't worry too much if the gearbox sounds noisy in neutral and third gear.

Pete

Don't worry too much if the gearbox sounds noisy in neutral and third gear.

Pete

1E75339 UberLynx D-Type; 1R27190 70 FHC; 1E78478; 2001 Vanden Plas

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |

#13

Hi there.

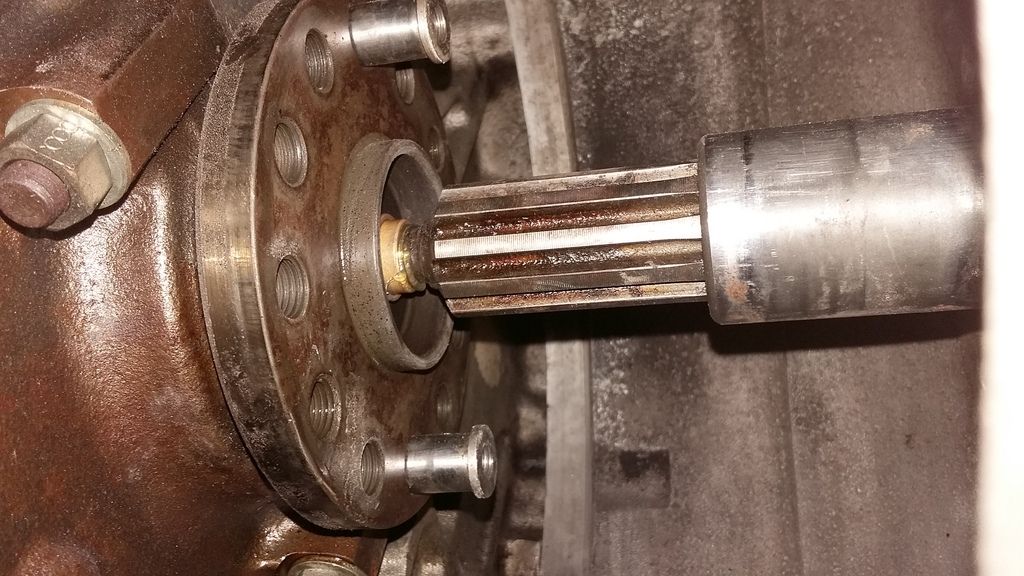

I ve received the 2 bushes.

It sounds good as you can see on the pictures :

Bush in place

And the gearbox and bellhousing back on the engine

I now have to decide if I use the standard flywheel I have (but with 2 broken tooth and I dont know how to repare them...) or If I buy a fidanza one. I ve placed a question on this part.

Cheers

I ve received the 2 bushes.

It sounds good as you can see on the pictures :

Bush in place

And the gearbox and bellhousing back on the engine

I now have to decide if I use the standard flywheel I have (but with 2 broken tooth and I dont know how to repare them...) or If I buy a fidanza one. I ve placed a question on this part.

Cheers

Le chemin sera long!...

| Link: | |

| BBcode: | |

| HTML: | |

| Hide post links |