Despair, despair, despair, when opened the QH had the same fault as those from eBay and SNG obviously Bob Hodgins had purchased some old stock and I had the new version.

As a general point I have great respect for the designers and engineers who created the E Type and if they decided to use a more angulated TRE then there was a good reason for it. The premise that distributors 'have not had a problem with the product' does not address the fact that some defects in design or construction only show themselves over time (as we all know from the 'Call Backs' in motor vehicles and domestic appliances) and that as most classic cars do only a small mileage over a year as compared to their daily drives it maybe some years before stress and strain on the TRE's have an effect.

My options appear to be:

1 Put back on the original ends.

2 Inspect the originals and see if I can engineer the eBay ones to something similar (not without risk) and I am unsure how to dismantle the TRE.

3 Ask round on the forums in case someone in the UK has a set of correct ends and is willing to sell them on.

4 Take the risk and put on the ones I purchased and live with it as a lot of E Type owners must be doing.

As a side note, those purchasing the various makes of TRE's should check the length from the flat area where the nut on the track rod will butt against to the centre of the grease nipple nut, they vary. The original is 81 mm, eBay 85 mm, SNG 83 mm and QH 79 mm.

I think if I do not get any response re option 3 then I will opt for option 1, tidy the ends up and put them back on as I just do not trust the suppliers to come up with the correct ones. Option 2 is probably not practicable and option 3 will just encourage the production of more ill designed, potentially dangerous parts. It is my intention to send back the SNG and QH parts with a suitable letter but first I need a reality check by placing my observations on the forum.

Sorry about the length of the article.

John

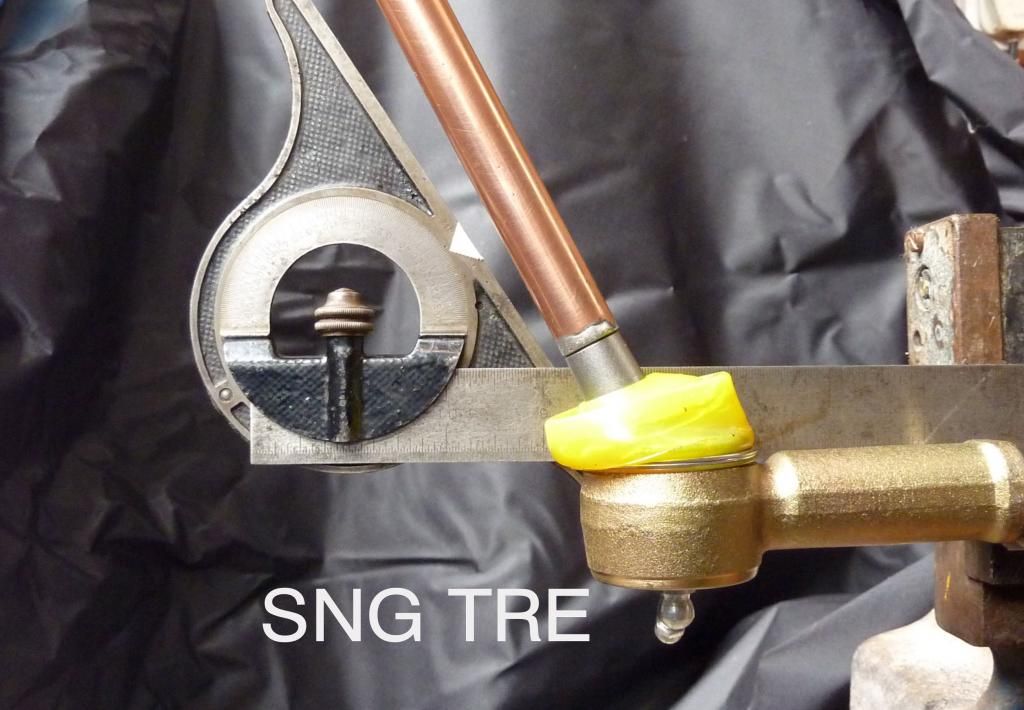

The tube has been added for clarity.

The original is on the right, note the scooped out recess, the other is the eBay TRE.

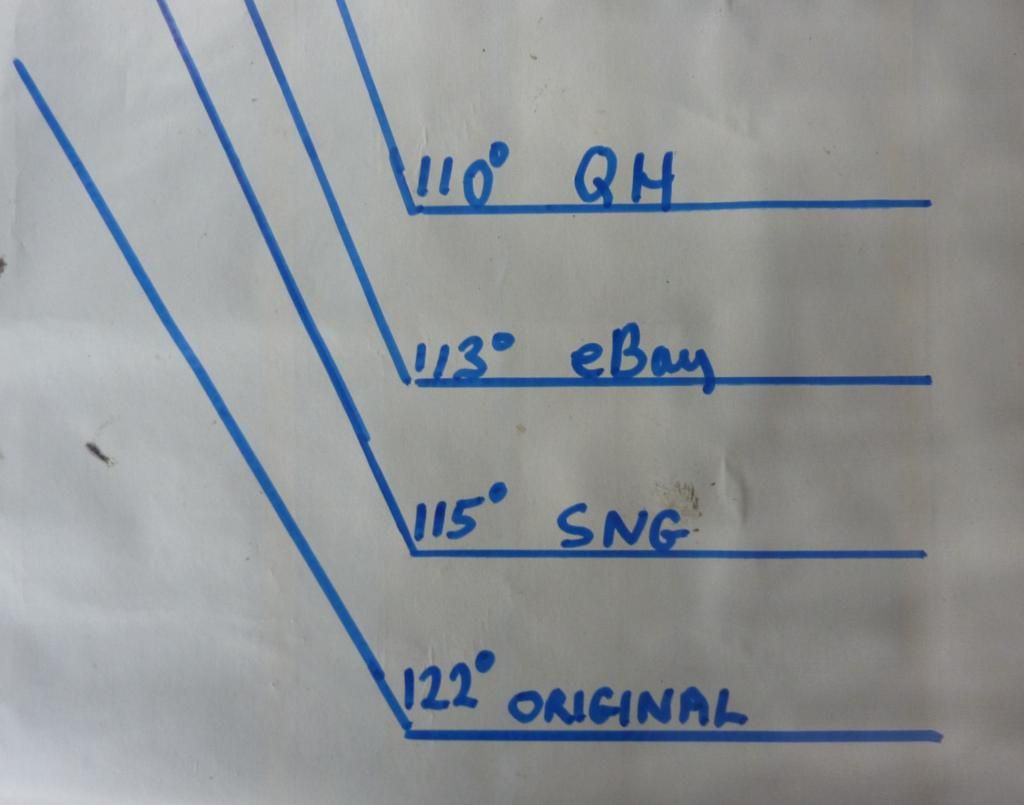

Varying lengths of the different TRE's

The open angles of the various TRE's which may vary + or - due to crude way of measuring.